Reading time: 7 minutes. Views 2.5k. Published 06/24/2018

Construction work is a complex process, which is accompanied by the preparation of related documentation. Such documents include projects for the future facility, contracts for the supply of raw materials and consumables, and other acts. There are special schedules for construction work, which indicate the amount of energy and labor resources spent. In this article, we propose to consider the question of what the production and technical department (PTO) does.

PTO is a commonly used abbreviation that stands for production and technical department

What is PTO

The main task of the production and technical department is to prepare for the various stages of construction work. According to experts, this department is a fundamental structural unit of companies operating in the construction industry. The task of the employees of this division is to process primary information about the implementation of the project A. This means that PTO employees accept design documents from the customer, study the estimate and issue a permit to begin construction. These tasks are performed at the stage of preparation for construction work.

Upon completion of the work, technical and technical equipment engineers generate documents on the operational characteristics of the facility. Next, all documents are transferred to the customer along with the object itself. The task of these specialists is to analyze incoming applications and evaluate them for compliance with various standards established by regulatory authorities. In addition, employees of the production and technical department have the right to hold tenders and competitions among suppliers for construction materials and raw materials. At each stage of construction, the task of engineers is to calculate the labor costs necessary to implement the project.

During the construction itself, employees of this department monitor the work process and assess the amount of material resources used. In case of deviation from the estimate, engineers need to develop a corrective action plan. All information obtained during the analysis is used in the formation of management accounting. Based on this information, work reports and internal statements are prepared, according to which employees receive wages.

The VET department (the transcript sounds like the production and technical department) performs many different functions. The task of this unit is to obtain permits for various events, tenders and examinations. Construction work involves large internal and external document flow between the contractor and the customer. Employees of the department in question may be tasked with collecting documents, according to the list prepared by the customer.

Main tasks

As mentioned above, the TVET department has many different responsibilities. Among them, it is worth highlighting the assessment of technical and economic parameters, as well as technical accounting and the formation of schedules for repair work. In addition, it should be highlighted:

- Formation of technical documents.

- Control over the implementation of various standards.

- Controlling the rate of consumption of energy resources and building materials.

- Submitting applications for the purchase of additional equipment and consumables.

VET is part of the structure of construction companies, installation, energy and industrial enterprises, and is also represented in housing and communal services organizations

VET is part of the structure of construction companies, installation, energy and industrial enterprises, and is also represented in housing and communal services organizations According to experts, the most difficult task falls on the engineers of this division. The main task of engineers is the formation of design documents and related applications in the form of calculations and estimates. In addition to handling paperwork, engineers need to monitor the production process and assist with installation procedures. In addition to all of the above, they are responsible for negotiating with business partners and subcontractors.

Production and technical department, functions:

- Development of a strategy for introducing innovative technologies into the production process.

- Monitoring the execution of work involving subcontractors.

- Conducting instructions.

- Control of the construction work plan.

As practice shows, employees of the division in question must interact closely with the accounting department. Such cooperation allows for timely scheduled calculations, on the basis of which reporting documents are generated.

Department structure

Employees of this department can be divided into two conditional groups. The first group is engaged in preparation for production, drawing up designs for future construction projects. The second group is engaged in drawing up estimates and concluding contracts. The structure of the unit itself is formed by the management of the department. When forming a staff, the specifics of the company’s activities and a number of additional economic factors are taken into account. Next, the staffing schedule is agreed upon with the general director of the company. After approval, the structure of the department is approved by issuing the appropriate act.

Functional responsibilities within the department are distributed according to internal instructions. The head of the production and technical department is responsible for the development and implementation of these documents.

Production and technical department in construction

As a rule, in the absence of an estimate and contractual unit, the responsibility for drawing up estimates is assigned to the production service. Employees of this department participate in preparations for negotiations, during which a contract is concluded. At this stage, the customer must transfer technical documents to the contractor to analyze their compliance with the existing drawings.

If inaccuracies and errors are identified, special reports are drawn up and sent to the customer.

The main goal of the department and its employees is to monitor all areas of production

The main goal of the department and its employees is to monitor all areas of production At a further stage, the contract itself is drawn up, to which an estimate of the future project is attached. The annex to the agreement between the parties must fix the cost of services and the guaranteed time frame for fulfilling obligations. The received technical documents are registered in special journals. They are then used as the basis for obtaining permits for construction work.

The VET department in construction is involved in engineering training. At this stage, the amount of work that must be completed within a month is determined. For this purpose, calculations are prepared on the costs of energy and labor resources. Next, consumables and necessary raw materials are purchased. At this stage, a summary statement is filled out, which records the cost of cement, reinforcement, precast concrete and other consumables. Before the construction itself, a special statement is created where the volume of work performed will be recorded. This statement must be laced and numbered, and also contain the signature of the company owner and company seal.

At the end of the above period, engineers check the work completion certificates received from subcontractors. These acts are used to process all project documentation. These actions are carried out every month in order to control the construction work. As a rule, most customers try to hire those companies that have a design department in their structure. If the order is related to the repair or reconstruction of an object, the technical maintenance engineer draws up a defect report for future work.

After agreeing on various issues related to the future project, VET workers prepare an estimate. At the next stage, the work is coordinated with the fire inspectorate and the SES. Next, a contract is concluded, on the basis of which the contractor begins to fulfill its obligations.

Those cases where there is a division within an organization that produces its own products deserve special attention. In this case, VET workers are tasked with calculating the final cost of goods. During such calculations, it is very important to take into account the cost of each product.

Among the main responsibilities of VET in the construction industry, it is worth highlighting the preparation of acts for obtaining permits. This department also develops various documents for participation in competitions. Such documents include estimates, licenses and commercial invitations. Engineers of this division take part in conducting regular inventory, and also interact with various regulatory authorities and contractors. In some cases, employees of this department are tasked with analyzing estimates and projects of third-party companies. To perform these actions, an appropriate license is required.

Taking into account the peculiarities of this or that area of work of a technical equipment engineer, the requirements for his qualifications are serious.

Taking into account the peculiarities of this or that area of work of a technical equipment engineer, the requirements for his qualifications are serious. Conclusions (+ video)

The production and technical service of a construction company is engaged in the generation of documents necessary for each stage of construction. These materials are used to transfer to the verification commission and the customer himself. All calculations and analyzes attached to the acts form the basis of the final package of documents. The technical department is headed by a technical director, who can occupy the position of chief engineer of the company. Based on all of the above, we can conclude that every employee of this unit must have a higher education.

In order to understand what a technical equipment engineer does and is responsible for (such a specialist must be present in any production or construction company), you first need to understand the main functions and features of the department where he works.

Production and technical department (PTO) - what is it for?

The production and technical department is engaged in the preparation of production and construction. The main functions of the VET are:

PTO, based on design estimates, works on projects and technological maps. One of the important areas of VET is taking into account the most rational use of the latest developments and technologies (construction machines and mechanisms, various devices, innovative methods of performing work). In addition, PTO employees must not only constantly monitor the progress of projects implemented by various subcontractors, but also provide the necessary instructions regarding work on sites.

VET workers, collaborating with planning departments and accounting departments, make various calculations for applications and plans, and draw up reporting documentation.

The responsibilities of the department include:

- maintaining technical records of the operation of various equipment;

- preparation of technical reports;

- analysis of technical and economic performance indicators;

- planning equipment repair schedules;

- monitoring compliance with standard costs of materials;

- timely preparation of requests for necessary materials or equipment parts.

Among all the employees of this department, the most complex types of work are performed by VET engineers.

Why do you need an engineer position in the department?

What is a technical equipment engineer? First of all, this is a position that is needed to carry out the necessary calculations and quality control of various types of work in the production and technical department. It should be occupied by a person who has a special education and work experience in this field for at least a year, since not everyone can know all the nuances of production and the features of performing various construction and installation works.

What knowledge should a VET specialist have?

A technical equipment engineer is a person who is well versed in legislation and regulations (he regulates the activities of all construction departments and organizations). In addition, he must understand all the specifics and features of the economic and technical development of his enterprise (specialization, core area, promising areas) and its capabilities (production capacity). The engineer must understand all the intricacies of the development and subsequent approval of plans for construction work.

In his professional activities, an engineer must take into account the specifics of construction (technology and methods of implementation), as well as know all the norms and regulations for the implementation of construction work approved by law. He controls the quality of implementation of construction projects, follows the procedure for the development and subsequent execution of various technical documentation (design, estimate, etc.) and maintains accounting documentation. In addition, he must draw up interim and final reports on the completion of all work regarding the approved project.

Regulatory documents regulating the activities of a technical equipment engineer

There are certain regulations and laws that must be followed by any person holding such a position. This:

What types of work does a VET engineer perform?

First of all, a person holding the position of engineer is obliged to conduct systematic supervision over the level and quality of various production or construction works, timely check the compliance of the volumes, designs and terms of the work performed according to previously approved documentation (project, estimate, drawings, standards, norms, technical conditions, rules, etc.). The engineer also monitors compliance with labor safety standards and regulations at the production site or construction site.

If during the implementation of the project there is a need to change it, the engineer must promptly agree on all issues related to the replacement of products, materials, structures, mechanisms, etc. (in this case, the quality of work should not be reduced in any way). If various problems arise during construction work (delays missed, quality deterioration, various violations), the specialist analyzes all possible causes and factors for their further elimination.

Features of budgeting and technical methods of work

The responsibilities of an engineer include performing various calculations, as well as accepting completed construction and production work. He coordinates the estimate and cost calculation of all necessary materials and equipment between the organization that prepared the project and the customer.

In addition, the technical equipment engineer participates in the commission for commissioning of the finished facility. He is also responsible for ensuring that preliminary calculations correspond to actual costs. If during the implementation of the project there is a need to include additional financing or introduce any new types of work, the engineer justifies this and makes all the necessary calculations.

What rights does a production and technical department engineer have?

The department engineer has the right to give instructions and tasks to employees in order to fulfill their functional duties. He can also control all stages of construction and production work (timeliness of completion, compliance with norms and regulations, quality level). In addition, a specialist can at any moment demand from an enterprise or organization additional information and the necessary documentation to promptly carry out his work. A technical equipment engineer can seek help from other organizations and companies to resolve various issues that are within his competence.

If during the implementation of a project a specialist sees additional opportunities and ways to improve construction and installation work, he can submit all his ideas and proposals for consideration by the management of the enterprise (organization, company, etc.).

Level of responsibility for quality of work

The PTO engineer is responsible for:

- failure to perform (or dishonest performance) of one’s official duties;

- negligent attitude towards performing work;

- non-compliance with regulations (laws, instructions, orders, regulations and other similar regulations);

- disclosure of trade secrets and confidential information;

- violation of the labor code (internal regulations, discipline, safety precautions, etc.).

- monitoring the production process.

In any organization, the production and technical department is responsible for planning production activities, its technical support and operational management. This department is an independent division of the organization and reports to its immediate manager or his deputy. At the same time, he constantly interacts with other departments and services of the organization. The production and technical department is guided in its work by current legislation, acts of the legal code, specialized methodological materials and organizational documents of the enterprise.

Who is a VET engineer?

This is a specialist who participates in research and scientific development of VET and works with estimates, projects, technical documentation and the like. He is responsible for the collection and analysis of scientific and technical information, as well as for carrying out the necessary work within a clearly established time frame and its quality.

The VET engineer is also the leader of the work on schematic design of all kinds of scientific and technical developments. He oversees the testing of new devices and describes their operating principles and technical characteristics. In addition, he is responsible for compliance with safety regulations during the implementation of new developments. Collecting the necessary documents to file a patent for a new invention is also his job.

What is expected from a technical equipment engineer?

An employee of such a high technical level is obliged to constantly improve his knowledge by studying various specialized literature and staying up to date with the latest scientific and technical achievements. The duties of a VET engineer include participation in conferences, including international ones, seminars and other similar events for the exchange of professional experience. He is also required to prepare publications on new scientific discoveries and developments. His presence is necessary during various examinations.

A VET engineer, of course, must have a technical mindset, be well versed in technical terminology and be able to competently draw up any documentation. In addition to all this, he needs to navigate the labor legislation of his country.

Of course, developing technical projects is not done alone. A whole group of specialists participates in it. Therefore, a VET engineer must, among other things, be sociable, hear the point of view of other specialists and find a common language with the team.

Skill level by category

A category III VET engineer can be a person with a higher technical education without work experience or with a secondary technical education and three years of experience as a category I VET technician, advanced training by at least one level within five years of work and a professional certificate.

A Category II VET engineer must have a higher technical education, three years of professional experience, at least one advanced training within five years and a professional certificate.

For a VET engineer of category I (highest) similar requirements are imposed, but they are also supplemented by the need for three years of experience as a VET engineer of category II. The lead technical engineer, who supervises junior employees and other department engineers, must, of course, have deep and up-to-date technical knowledge and sufficient professional experience.

Types of higher technical education

In the production and technical department, productive work is impossible without a quality education. A technical equipment engineer can specialize in the following areas:

- construction;

- transport construction;

- civil and industrial construction;

- production of building materials, products and structures;

- drainage and water supply;

- hydraulic engineering;

- ventilation and heat and gas supply.

If necessary, a person who has a technical education in any of these specialties can undergo retraining in accordance with the position he will occupy.

Job description

A job description is a document that is filled out when a person is hired and with which he must be familiar. Among the general provisions that are mentioned, first of all, what professional knowledge he should have. It also describes his duties, responsibilities and rights, the basic conditions of his work and the criteria by which the results of his work and business qualities are assessed.

Main responsibilities

Responsibilities of a technical equipment engineer include:

- High-quality performance of job duties specified in the employment contract and job description.

- Compliance with labor discipline.

- Compliance with labor standards.

- Compliance with established work procedures.

- Compliance with all safety requirements.

- Carefully handle the property of the employer and colleagues, as well as property for which the employer is responsible.

- Timely notification to the employer or the head of his department about situations that pose a threat to human life or to the safety of property for which the employer is responsible.

An engineer has a great responsibility and anyone who decides to master this profession must be ready for it. Depending on the specialization, the professional responsibilities of different engineers vary. For example, a technical equipment engineer in construction must perform the following tasks:

- control that the cost of construction or installation work carried out according to the project and estimates corresponds to their quality and volume;

- take part in the preparation of construction subcontracts and contracts;

- accept and issue the necessary design and estimate documentation;

- improve your qualifications and expand your professional knowledge.

Basic rights

Of course, when applying for a job, a person must have a clear understanding not only of his responsibilities, but also of his rights. Then he will have satisfying, productive work waiting for him.

A VET engineer under an employment contract has the following rights:

- To give him a job.

- On timely salary in full.

- To a safe workplace in terms of state labor protection standards.

- For professional training, advanced training in the manner established by law, and retraining in the relevant technical specialty.

- For rest, which, for example, includes a normal working day, weekly days off and paid annual leave.

- To create trade unions and join them in order to protect their rights, professional interests and freedoms.

- To resolve various labor disputes of a collective and individual nature, as well as to strike as provided for by law.

- For compulsory social insurance.

- To compensate for damage, including moral damage, which was caused as a result of the performance of professional duties, in the amount and manner established by law.

Working conditions

The job description of a technical equipment engineer stipulates the following working conditions:

- working hours in accordance with established labor regulations;

- characteristics of working conditions at the workplace;

- the employee’s obligation to go on professional business trips;

- emergency procedures;

- relationships with other team members in accordance with their positions;

- instructions on who will be temporarily assigned the duties of the employee in the event of his absence.

Criteria for assessing professional qualities and labor productivity

The main criteria for assessing the professional qualities of an engineer are:

- qualification level;

- professional work experience in a technical specialty;

- professional competence;

- level of compliance with labor discipline;

- flexibility in performing work and the ability to quickly find sometimes non-standard solutions to complex production issues;

- ability to work with documentation;

- work ethics, creativity, initiative and other important professional qualities.

The main criteria for assessing the results of an engineer’s work are:

- quality of work performed;

- timely performance of official duties;

- level of labor productivity.

The engineer's business qualities and work results are assessed in accordance with objective indicators and the impartial opinion of the immediate supervisor and the team with whom he works.

As you can see, the work of an engineer is quite complex and responsible. When deciding to become an engineer, you need to realize that this profession will require complete dedication. But it will also bring satisfaction, since in any organization a technical equipment engineer is an irreplaceable worker whose work is highly valued.

The main task of the technical department is the constant improvement of technological production processes based on the introduction of the latest achievements of science and technology. In accordance with the specified main task, the technological department is assigned:

Organization of technical preparation of production and other types of core activities of the enterprise, ensuring acceleration of the growth rate of labor productivity;

Coordination of the work of the enterprise’s technical services to test new technical means, create and develop new types of products, complex mechanization and automation of production;

Drawing up current and long-term plans for the development of the enterprise;

Review and approval of enterprise design documentation for equipment modernization;

Monitoring compliance and execution of contracts.

Job description of the head of the technical department.

I. GENERAL PROVISIONS

1.1. The head of the technical department belongs to the category of managers

is hired and dismissed from work by order of the director of the enterprise.

1.2. A person who has

higher technical education and work experience in technical training

production in engineering, technical and management positions for at least 5 years.

1.3. The head of the technical department reports to ________________

__________________________________________________________________.

1.4. In his activities, the head of the technical department is guided by:

Regulatory documents on technical preparation of production;

Methodological materials relating to relevant issues;

Charter of the enterprise;

Labor regulations;

Orders and instructions of the director of the enterprise (direct manager);

This job description.

1.5. The head of the technical department must know:

Resolutions, instructions, orders of higher authorities, methodological, regulatory and other guidance materials on technical preparation of production;

Directions and prospects for the development of the industry and enterprise;

Technology of production of the enterprise's products;

Production capacities and operating modes of equipment, rules of its operation, methods for identifying and using production reserves;

Technical requirements for raw materials, materials and finished products;

Labor organization requirements when designing technological processes and equipment;

Organization of technical preparation of production;

The procedure for accepting equipment into operation;

Methods for determining the economic efficiency of introducing new equipment and technology, labor organization, rationalization proposals and inventions;

Experience of leading domestic and foreign enterprises in the field

technical preparation of production, labor organization and management;

Fundamentals of labor legislation;

Rules and regulations of occupational health, safety, industrial sanitation and fire protection.

1.6. During the absence of the head of the technical department, his duties

carried out in the prescribed manner by an appointed deputy, who bears full responsibility for their proper execution.

II. FUNCTIONS

The head of the technical department is assigned the following functions:

2.1. Management of the technical department.

2.2. Organization of technical preparation of production or other types of core activities of the enterprise.

2.3. Coordination of the work of technical services of the enterprise.

2.4. Management of planning of technical development of the enterprise.

2.5. Organization of work to improve the qualifications of department employees.

2.6. Ensuring healthy and safe working conditions for subordinates

performers, monitoring their compliance with the requirements of legislative and regulatory acts on labor protection.

III. JOB RESPONSIBILITIES

To perform the functions assigned to him, the head of the technical department is obliged to:

3.1. Organize technical preparation for production or other types of core activities of the enterprise, ensure acceleration of the growth rate of labor productivity, reduce labor costs for production, improve the quality of products, works (services).

3.2. Coordinate the work of the enterprise's technical services to test new technical means, create and develop new types of products, comprehensive mechanization and automation of production, planning the implementation of scientific and technical achievements, new equipment and progressive technology.

3.3. Manage the current and long-term planning of the technical development of the enterprise and its production base.

3.4. Manage the preparation of technical specifications for the design of newly built production facilities, structures, technical means, expansion, development and reconstruction of existing ones, for the introduction of mechanization and automation means.

3.5. Review and coordinate design documentation for equipment modernization and workplace rationalization.

3.6. Monitor the conclusion and execution of contracts related to the introduction of new equipment, as well as the financing and correctness of calculations of the economic efficiency of measures for the development of new equipment and technology, new types of raw materials and finished products.

3.7. Participate in the development and implementation of resource-saving technologies in production, progressive consumption rates for the main types of raw materials and materials, in studying the causes of defects and production of products of reduced quality and grade, in the development of measures to improve the quality of products (works, services) and more efficient use of production capacities.

3.8. Perform in the absence of independent design and

technological departments are the functions of their managers.

3.9. Direct the activities of departments dealing with issues of product standardization, scientific and technical information, as well as the organization of patent and invention work.

3.10. Manage, coordinate and direct department employees

activities of enterprise departments providing technical preparation of production.

The head of the technical department has the right:

4.1. Get acquainted with draft decisions of the enterprise management concerning the activities of the department.

4.2. Submit proposals for improvement to management for consideration

activities of the enterprise and technical department.

4.3. Sign and endorse documents within your competence.

4.4. Interact with managers of all structural

divisions of the enterprise, receive information and documents necessary to perform official duties.

4.5. Submit for consideration by the director of the enterprise ideas about

appointment, relocation, dismissal of department employees, proposals for their promotion or imposition of penalties on them.

4.6. Require the management of the enterprise to provide assistance in the performance of their official duties and rights.

V. RESPONSIBILITY

The head of the technical department is responsible for:

5.1. For failure to perform (improper performance) of their duties

responsibilities provided for by this job description, within the limits determined by current labor legislation.

5.2. For those committed in the course of carrying out their activities

offenses - within the limits determined by the current administrative, criminal and civil legislation.

5.3. For causing material damage - within the limits specified

current labor, criminal and civil legislation.

Planning and Economic Department.

The economic planning department (PEO) is the headquarters of all planned work at the enterprise. He carries out long-term and current technical and economic planning of production, maintains statistical records, sums up and analyzes the results of production activities of the enterprise, workshops, and divisions.

The economic planning department organizes the work and manages the preparation of materials and the necessary initial data in all departments and services of the enterprise involved in the development of the technical industrial financial plan. He draws up planned tasks for all workshops of the main and auxiliary production and accepts their reports. The department organizes the preparation and implementation of economic accounting in the divisions and workshops of the enterprise, prepares materials for concluding contracts for the supply of products, exercises control and methodological guidance of shop planning bodies and planning units of other departments (design, chief mechanic department, etc.). Finally, the PEO corresponds and enters into contact with the planning authorities of parent organizations.

Based on the tasks of the technical industrial and financial plan, the production dispatch department (PDD) develops nomenclature and production tasks for workshops and production areas (with a non-shop management structure), sets deadlines and monitors the progress of these tasks.

In addition, PDO coordinates the work of all departments and services involved in providing production with everything necessary. An important task of PDO is to organize rhythmic production and release of products. For this purpose, operational records of production are maintained, dispatch control is organized, and prompt measures are taken to eliminate any deviations from the plan that arise.

Planning bodies of workshops - planning and dispatch bureaus (PDB) - carry out intra-shop planning. They issue production tasks to sections for short periods of time (a month or less), provide them with materials, systematically (daily) monitor the progress of production, and keep records and reports on the implementation of the plan.

The most important tool for improving planning in industry and at every enterprise at the present stage is the use of mathematical methods and electronic computer technology, the creation of automated production control systems (APS).

Speaking about the introduction of automated control systems as the most important direction for improving planning, we should not forget that an automated system is the highest form of production management, which, however, is not a “cure for all diseases.” A high level of planning is impossible if the issues of specialization of enterprise production are not resolved, there is no rational organization of production and labor, or the cost accounting system is inactive.

Therefore, improving planning is a complex problem that covers all aspects of an enterprise’s activities.

Like any enterprise, there is an economic planning department, which is headed by the head of the economic planning department, who belongs to the category of managers. A person with higher professional education and at least five years of work experience in the field of planning is appointed to the position of the economic planning department. Appointment to the position of department head is made by order of the director of the enterprise. The planning and economic department of the enterprise carries out:

Current and long-term planning of technical and economic indicators of the enterprise and monitors the timely delivery of established indicators to the workshops;

Provides accounting and control over the implementation of planned tasks of the enterprise and workshops;

Analyzes the results of production activities of the enterprise and workshops;

Conducts the development and implementation of work plans for production and quality of products;

Conducts an analysis of the technical and economic indicators of the work of workshops, identifying the possibility of producing products, increasing productivity and education, reducing production costs;

Develops measures for planning reserves, organizes calculations of economic efficiency from measures for the enterprise and in general, makes calculations to determine the effectiveness of the introduction of new technology and rationalization proposals,

Provides preparation of periodic and daily reporting of production and economic activities and according to statistical reporting forms;

Prepares planned costing of goods, products and services for the current year, broken down by quarter;

Performs calculations necessary for drawing up current plans and requests for material resources;

Brings norms and standards for the use of resources to the lower divisions of the enterprise and periodically revises them as technology improves and labor organization in production improves;

Conducts daily accounting of the implementation of technical and economic indicators for the enterprise and workshops.

Such work" Sergey Demyanov

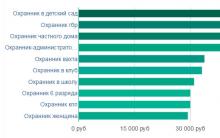

Unsweetened life Can a diabetic work as a security guard?

How long does it take for a parcel from China to Russia from Aliexpress?

How to find a good job - a detailed guide for those who want to get their dream job!

Presentation on the topic “Acmeism