Let's talk today about a necessary and in-demand profession that does not come to our attention very often. Train compiler - who is he, what does he do, what is his functionality? Let's try to consider the main features and nuances of activities in this position.

There is such a job - train compiler

If we turn to the official terminology, then its task is to form and disband the rolling stock of the train, that is, rearrange the cars in the required order. Of course, this occupation requires certain specific knowledge, that is, this profession can be learned like any other.

Such work is classified as difficult and very responsible. The main task of the compiler specialist is to send the train on its way in a timely manner. He is responsible for the correct completion of the train, its integrity, the safety of movement and the accuracy of maneuvers. Each of the trains must be checked on time, the cars must be unfastened and secured.

Main functionality

Let's look at the main responsibilities of a train maker. This position assumes many functions - after all, it is this position that ultimately determines the efficiency of railway traffic. The main responsibilities of the specialist are to move non-centralized switches, protect train cars with brake shoes in a timely manner, take care of the safety and security of each train, couple and uncouple cars, and manage locomotive maneuvers.

The amount of work depends on the size of the station where the train compiler works, as well as the region where it is located.

What exactly is he doing?

How does a train designer's working day begin? Every morning, workers are assembled for a special meeting, where they all receive safety instructions. Then everyone is given strict inventory and assigned work tasks in the form of arranging the cars in a certain order.

Further activities to be carried out during the working day are agreed upon with the station duty officer. The day-to-day responsibilities of a train operator consist of servicing and checking wagons, as well as coupling and uncoupling. Any of his actions must be coordinated with the duty officer using a walkie-talkie.

As you can see, with so much work you definitely won’t get bored. While servicing cars and preparing trains for dispatch, he must also fill out the accounting log on time and without errors and check the cars he receives.

All this activity requires mandatory personal presence. The train compiler's instructions require him to be on duty under the control of the station master. But at the same time, the level of personal responsibility in this profession is very, very high.

Having accepted a shift, the train compiler must note the condition and location of each car, the safety of special seals and the presence of equipment. Only after fully fulfilling his official functions - arranging the cars in their places, checking the train, etc., he has the right to hand over duty.

Personnel decides a lot...

What personal qualities are required for someone who wants to occupy such a position? Any profession presupposes the presence of certain character traits. What exactly should a train compiler have? Of course, first of all - a conscientious attitude to business, accuracy and responsibility.

Other important traits that you can’t do without in this type of work are resistance to stress and the ability to get along with people. Supervision of lower level personnel or those assigned as assistants is sometimes required. Calmness and the ability to maintain composure in any situation are qualities that are in demand in any profession, but in the conditions of the railway with its complex rhythm and many stress factors, these advantages become especially relevant.

Let's go study

How does one acquire the profession of “train maker”? Despite the apparent simplicity of the job duties, a person from the street will not be hired for such a job. Appropriate education will definitely be required. So, where can you master this interesting specialty?

They teach it in technical schools or colleges, and you can enroll there after the 9th grade. The training course program of the future compiler is devoted primarily to the issues of railway traffic safety and consideration of all the smallest technical nuances of this area. Significant attention is devoted to mastering how and under what circumstances special signals are used - manual and audio.

What else will they teach you?

The future Russian Railways train designer is learning how to direct the movement of a locomotive. He must know the rules for using brake shoes, be able to work with portable radios and learn all the features of handling them. A very important point is the correct technique for securing trains to the rails.

Much attention in the course program is given to the issues of loading and unloading, as well as ensuring the integrity and safety of the transported cargo. Lectures will be given to the future student on subjects such as labor protection, design and maintenance of freight cars, and life safety.

About skill levels

This job - train compiler - like most similar ones, presupposes the existence of qualification categories of 4. Those who have the lowest (third) category may not work on every railway. Those that have public status are still closed to such workers. The area of activity of a novice specialist should not have too much traffic.

Those with the fourth category are allowed to work on the same types of railway transport, but in regions with greater traffic intensity, and therefore the complexity of the work increases noticeably.

When skills increase

Specialists with the fifth category are allowed to service public railway transport, but such stations must be located in one of the least active areas, similar to the option with the third category.

The highest category - sixth - implies access to the most complex work. Its holder is admitted to the position of train compiler in any area, even the most complex and highly traffic intensive, and can work with public transport.

The management can entrust highly qualified workers with the management of employees who have a lower rank, but in general everything depends on the region where the station is located and its status.

Rights and guarantees

What about the rights of those working in such a position? Of course, there are them too. The most important of these for a train compiler is the right to request from management everything that is necessary for work. This equipment includes a set of signal lights with a yellow flag, a walkie-talkie, a portable radio station and, of course, a special work uniform. The list can be supplemented with other accessories. If these items of equipment were not issued, the employee has the right to complain about non-compliance with labor safety standards.

Other guaranteed rights of an employee include the possibility of timely and prompt reception and delivery of duty. The specialist’s working hours must fit into the standard working hours, according to the Labor Code of the Russian Federation.

About the cons

What disadvantages can we talk about in relation to this profession? The main problem of such a position, of course, is the high level of responsibility. This is a very, very difficult job, and the difficulty increases the higher the employee’s rank. At the same time, with increasing qualifications, professional experience naturally increases, which makes it possible to consider the responsibilities not so exhausting.

Another disadvantage is the large amount of hard physical labor. This is truly a male profession. Often you have to literally work with your own hands. And of course, a shift schedule with nights out cannot but affect the state of health and general well-being.

Train maker: salary and more

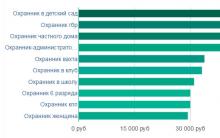

But not everything is so scary, because the shortcomings of any profession are compensated by its advantages. What advantages can we talk about in this case? As you know, one of the most important characteristics of any job is the level of its payment, which in this case cannot be complained about. For hard, physically exhausting work, a train compiler can receive really good money.

Unfortunately, we are not able to provide specific figures here. They can vary significantly depending on the station, the area where it is located, and the qualification level of the worker. But on average, such a specialist receives at least 18 thousand rubles per month.

Another bonus is that this profession is always in demand on the labor market. Qualified specialists capable of establishing a well-organized operation of a railway station are not found very often. Such people will always find a job. Often representatives of this profession “attach their hearts” to their favorite work and work for many years at the same station in a well-knit team of like-minded people, which also cannot but be attributed to its positive aspects.

I approve (name of the organization, enterprise, etc., its exact (surname, initials) organizational and legal form) _________________________ (director or other official authorized to approve the job description) " " _____________ 20__ m.p. Job description of a train compiler of the 6th category _____________________________________________________________________ (name, legal form of the enterprise, organization) This job description has been developed in accordance with the provisions of the Labor Code of the Russian Federation, the legislation of the Russian Federation regulating the labor activities of employees in the field of railway transport in the Russian Federation, including: Federal Law of January 10, 2003 N 17-FZ "On Railway Transport in the Russian Federation", Federal Law of January 10, 2003 N 18-FZ "Charter of Railway Transport of the Russian Federation", Regulations on the Discipline of Workers of Railway Transport of the Russian Federation , approved by Decree of the Government of the Russian Federation dated August 25, 1992 N 621, Order of the Ministry of Railways of the Russian Federation dated March 5, 2004 N 7 “On approval of the Regulations on the peculiarities of working hours and rest time, working conditions of certain categories of railway transport workers directly related to traffic trains", Order of the Ministry of Railways of the Russian Federation dated November 17, 2000 N 28 C "On the procedure for testing knowledge of the Rules for the technical operation of railways of the Russian Federation, other regulations of the Ministry of Railways of Russia and the Regulations on the discipline of railway transport workers of the Russian Federation", Decree of the Government of the Russian Federation dated September 8 1999 N 1020 “On approval of the list of professions and positions of workers ensuring the movement of trains, subject to mandatory preliminary, upon entry to work, and periodic medical examinations,” as well as other regulations governing labor relations in the Russian Federation. 1. General provisions 1.1. A person with a special professional education without any work experience requirements is accepted for the position of train compiler of the 6th category. 1.2. A train compiler of the 6th category belongs to the category of technical performers and in his work activity reports directly to __________________________________________________________. (position of manager, name of railway transport organization) 1.3. The position of train compiler of the 6th category is indicated in the List of professions and positions of workers ensuring the movement of trains, subject to mandatory preliminary medical examinations upon entry to work. A train compiler of the 6th category is not allowed to work if he has not passed a mandatory medical examination or there is a conclusion from the Higher Electoral Commission on professional unsuitability. 1.4. A train compiler of the 6th category is hired and dismissed from work by order of _______________________________________________________. (position of the manager and name of the railway transport organization) 1.5. A train compiler of the 6th category is guided in his activities by: - current regulations and methodological documents regulating the activities of railway transport, including the Rules for the Technical Operation of Railways of the Russian Federation dated May 26, 2000 N TsRB-756, Instructions for Signaling on Railways roads of the Russian Federation dated May 26, 2000 N TsRB-757, Instructions for the movement of trains and shunting work on the railways of the Russian Federation dated October 16, 2000 N TsD-790, Rules for the technical operation of industrial railway transport, approved by the Ministry of Transport on March 29, 2001 ., Instructions for signaling on industrial railway transport, approved N AN-23-R on March 30, 2001, Regulations on the discipline of railway transport workers of the Russian Federation, approved by Decree of the Government of the Russian Federation of August 25, 1992 N 621, Safe operation technology and repair of rolling stock of industrial railway transport N AN-25-R, approved on March 30, 2001, other regulations establishing the rights and obligations of railway transport workers; - Charter of railway transport; - Charter of the enterprise; - internal labor regulations; - orders and instructions from the immediate supervisor; - this job description. 1.6. A train compiler of the 6th category must know: - rules and regulations of labor protection, safety precautions, industrial sanitation and fire protection; - job description and technical and administrative act of the train compiler; - rules for the transportation of goods; - technological process of operation of serviced stations; - train formation plan; - arrangement of brake shoes and rules for using them; - the procedure for transferring non-centralized and centralized switches transferred to local management; - general information about the structure of wagons and containers; - plan, profile, specialization and capacity of the tracks, location of loading and unloading points for wagons in the serviced shunting areas; - rules for storing and using the radio station and other means of communication; - techniques and methods of providing first aid. 1.7. During the absence of a train compiler of the 6th category (vacation, illness, business trip, etc.), his duties are performed by a deputy appointed in the prescribed manner, who bears full responsibility for their proper execution. 2. Functions 2.1. The train compiler of the 6th category is assigned the following functions: - performing shunting work in busy shunting areas at high- and high-capacity mainline railway stations. 3. Job responsibilities 3.1. To perform the functions assigned to him, the 6th category train compiler is obliged to: - manage the movement of the shunting locomotive; - ensure the correct placement and coordination of the actions of workers participating in the maneuvers; - disband and form trains and groups of cars; - uncouple and couple wagons to trains, supply wagons to loading and unloading and other specialized tracks and remove them from these tracks; - rearrange cars and trains from track to track, from park to park and transfer them from one station to another; - secure and fence trains and cars standing on the tracks with brake shoes and remove them from under the cars; - participate in testing automatic train brakes; - carry out transfers during maneuvers of non-centralized switches that are not served by switch posts on duty or centralized switches transferred to local control; - uncouple cars when dissolving trains from hump yards; - regulate the thrust speed during the dissolution of the train, depending on the driving performance and weight of the cut; - ensure traffic safety, safety of rolling stock and cargo; - keep radio stations and signaling accessories clean and in good working order; - strictly follow safety and labor protection rules; - timely undergo mandatory medical examinations carried out by medical expert commissions of medical and preventive institutions of the healthcare system of the Ministry of Railways of Russia, to which ___________________________________________________________________ is attached in accordance with the order of the head of the railway; (name of the railway transport organization in which the train compiler is hired) - fulfill the individual conditions for admission to work prescribed by the conclusion of the EEC. 3.2. By order of the locomotive depot administration, a 6th category train engineer, if necessary (if there are signs of intoxication or illness), is required to undergo drug control or a full pre-trip medical examination. 4. Rights 4.1. A train compiler of the 6th category has the right to: - all social guarantees provided for by law; - demand from the management of the enterprise assistance in the performance of their official duties and the exercise of rights; - demand the creation of conditions for the performance of official duties, including the provision of the necessary equipment, inventory, etc.; - get acquainted with the draft decisions of the enterprise management concerning its activities; - submit proposals for improvement of the organization and methods of work performed by the enterprise management for consideration; - request personally or on behalf of the immediate supervisor the documents necessary to perform their official duties; - improve your professional qualifications. 5. Responsibility 5.1. A train compiler of the 6th category is responsible: - for failure to perform or improper performance of his job duties provided for in this job description - within the limits determined by the current labor legislation of the Russian Federation; - for causing material damage - within the limits determined by the current labor and civil legislation of the Russian Federation; - for offenses committed in the course of carrying out their activities, - within the limits determined by the current administrative, criminal, and civil legislation of the Russian Federation. The job description was developed in accordance with ____________________ (name, _____________________________. document number and date) Head of the structural unit _____________________________ (initials, surname) (signature) "__" ________________ 20_ Agreed by: Head of the legal department _____________________________ (initials, surname) (signature) "__" ________________ 20_ have read the instructions: _____________________________ (initials, surname) (signature) "__" ________________ 20_

These labor safety instructions for train compilers are available for free viewing and downloading.

1. GENERAL PROVISIONS

1.1. This Instruction was developed on the basis of the Rules for labor protection in the transportation of federal railway transport, approved by the Ministry of Railways of Russia on September 20, 2001 No. POT RO-32-CD-855-01.

1.2. These labor safety instructions have been developed for train assemblers performing shunting work on public and non-public railway tracks.

2. GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

2.1. Only male persons who have reached the age of eighteen years, who have undergone a mandatory preliminary medical examination (examination), introductory and initial briefings on labor protection, training in labor protection, and on-the-job training under the guidance of an experienced worker are allowed to perform shunting work on railway tracks. employee during the first 2-14 shifts (depending on the nature of the work, the qualifications of the employee) and an initial test of knowledge of labor protection requirements.

While working, the train compiler must undergo periodic medical examinations at least once a year, repeated instructions on labor protection at least once every three months, as well as unscheduled and targeted briefings on labor protection.

2.2. The train compiler must comply with the internal labor regulations established in the organization, as well as other regulatory documents in force in the organization (Regulations, standards, instructions).

2.3. The train compiler must know:

— the effect on humans of dangerous and harmful production factors and measures to protect against their influence;

— harmful effects of petroleum products and basic chemical cargoes on the human body, as well as signs of poisoning;

— requirements for industrial safety, electrical safety, fire safety and industrial sanitation;

— rules for the application and use of fire-fighting equipment and inventory;

— visible and sound signals ensuring traffic safety, safety signs, the procedure for fencing rolling stock, dangerous places;

— rules for providing first aid to victims;

— places to store a first aid kit or a bag with necessary medications and dressings;

— rules for staying on railway tracks;

— safe ways to perform shunting work;

— requirements of this Instruction.

2.4. The train compiler must:

- perform only the work included in his duties or assigned by the shunting dispatcher;

— apply safe work practices and technological operations that are provided for by the technological process and job responsibilities;

— manage shunting work on the formation and disbandment of shunting trains, rearrangement of cars, uncoupling and coupling of cars to locomotives, supply and removal of cars from (to) loading and unloading tracks of public and non-public use, ensuring personal safety, safety of people, safety of rolling stock during unloading shunting train with cars forward;

— ensure the correct arrangement and coordination of the actions of workers participating in maneuvers, based on their familiarization with the plan and methods of performing the upcoming shunting work;

— comply with the requirements of prohibitory, warning, directional and mandatory signs, inscriptions and signals given by vehicle drivers;

— keep the radio, equipment and personal protective equipment in good condition and clean;

— comply with fire safety requirements, have practical skills in using fire-fighting equipment and inventory;

- walk through the territory of the enterprise where shunting work is carried out along established routes, pedestrian paths, tunnels, passages and transitions;

— be extremely careful in areas where carriages and vehicles move;

— comply with the internal labor regulations and the established work and rest schedule;

- be able to provide first aid to the victim;

— know and comply with the requirements of these Instructions.

2.5. During the work process, the train compiler may be exposed to the following dangerous and harmful production factors:

— moving rolling stock, vehicles, mechanisms;

— location of the workplace at a height relative to the ground surface;

— increased noise level;

— increased level of vibration;

— increased dust and gas contamination of the air in the working area;

— increased or decreased air temperature in the working area;

— increased humidity and air mobility;

— insufficient illumination of the work area at night;

— physical overload;

— neuropsychic overload when performing work on railway tracks while trains are moving;

- tension and hard work.

2.6. The train compiler is provided with special clothing, shoes, flushing and neutralizing agents in accordance with the approved Standards and List (these documents are developed on the basis of standard industry standards and approved by the General Director).

2.7. The care and maintenance of personal protective equipment is carried out by the train compiler in accordance with the current regulatory document (approved Regulations or Standards).

2.8. The train designer must comply with the following fire safety requirements:

- smoke only in places specially designated for this purpose;

— do not use damaged sockets, switches and other electrical equipment;

— do not operate electrical wires and cables with insulation that is damaged or has lost its protective properties;

- do not use electric stoves, electric kettles and other electric heating devices that do not have thermal protection devices, without stands made of non-combustible materials;

- do not use non-standard (homemade) electric heating devices;

— do not leave electric heating devices plugged in unattended;

— do not use open flames or open heating devices;

2.9. The train organizer must immediately notify the shunting dispatcher or the head of the shunting area about any situation that threatens the life and health of people, about every accident that occurs at work, or about a deterioration in his health, including the manifestation of signs of an acute occupational disease (poisoning) . The procedure for action in the event of these situations is approved by the Regulations.

2.10. Meals should be taken in canteens, buffets or in specially designated rooms with appropriate equipment.

Before eating, you should wash your hands thoroughly with warm water and soap.

It is not allowed to store or eat food in workplaces.

2.11. While passing along the tracks or during shunting work, the train engineer must:

- distribute your attention between moving and performing your official duties;

- switch your attention from near space to more distant space to observe moving rolling stock.

The train compiler, knowing the properties of attention, must control his actions on the tracks and do his job safely.

It is necessary to take into account that when the body is tired, operational (momentary) memory and attention are impaired, vision, hearing, and coordination of movements decrease, human activity decreases, and drowsiness appears. Therefore, after finishing work, when passing along the tracks, through the tracks or along the route of the service passage, the train compiler must be especially careful and not allow his attention to be diverted from monitoring the moving rolling stock.

The train engineer should exercise special caution and attention when on the tracks in poor visibility, in heavy snowfall, fog and in the presence of strong noise created by operating equipment and passing rolling stock, especially in winter, when headgear impairs the audibility of signals and noise from the rolling stock.

If, while passing along an inter-track, the train compiler sees that even and odd trains are approaching him, he must go to the side of the road or to another inter-track so as not to find himself between the moving trains. If the train compiler finds himself between trains or locomotives moving along adjacent tracks, then he must immediately sit down or lie down on the ground between tracks.

In the dark, during fog, ice, or snowstorms, it is necessary to reduce your speed of movement along the tracks, increase caution, and pay attention to the sound signals given by locomotives, motor railcars or railcars.

When leaving premises or buildings that impair the visibility of the railway track, the train compiler must first make sure that there is no rolling stock moving along it.

After leaving the room at night, you need to wait some time (1 - 2 minutes) until your eyes get used to the darkness. It must be remembered that in between the tracks there are various devices: cable boxes, racks, choke transformers, limit posts, trays, ditches and other obstacles.

If, when passing through the territory of an organization where shunting work is being carried out, a spill or scattering of hazardous or harmful substances is detected, then you should go around them so that the wind does not carry vapors or particles of these substances towards you. Smoking must be avoided. Such dangerous and harmful substances include: gasoline, kerosene, fuel oil, diesel fuel, oil, acetone, technical alcohol and other flammable and combustible liquids.

2.12. When on railway tracks, the train engineer must comply with the following safety requirements:

- go to the place of work and back along established service passage routes, developed taking into account local conditions;

- when passing along railway tracks, walk along a wide inter-track, along the side of the roadbed or to the side of the railway track no closer than 2.5 m from the outer rail, while you must carefully monitor the movements of rolling stock on adjacent tracks, paying attention to objects protruding beyond the loading dimensions of rolling stock and the approach of buildings;

- comply with the requirements of safety signs and warning painting applied to structures and devices, pay attention to devices and objects located along the route (limit posts, flexible rod chutes, drainage trays and wells, alarm devices, centralization and blocking, communications and other obstacles );

- cross railway tracks only at right angles, without stepping on the head of the rail, after making sure that there is no rolling stock moving at a dangerous distance in this place;

— cross railway tracks occupied by carriages, using only crossing platforms with working steps and handrails;

- rise and descend from a transition platform or a special step, turning to face the car, having first made sure that there are no approaching rolling stock on the adjacent railway track and obstacles in the intertrack or on the side of the track;

- walk around groups of cars or locomotives standing on the railway track at a distance of at least 5 m from the automatic coupler;

— pass between uncoupled cars, if the distance between the automatic couplers of these cars is at least 10 m;

— pay attention to the indications of boundary traffic lights, sound signals and warning signs;

- once you are on the route of a train, before it approaches, move to the side of the track or to the middle of a wide inter-track at a safe distance.

— when rolling stock approaches, it is necessary to pay attention to open doors, sides of cars, tie-down wires and other objects protruding beyond the dimensions of the rolling stock.

2.13. While on the railway tracks, the train compiler is strictly prohibited from:

- cross or run across railway tracks in front of a moving rolling stock or immediately after a passing train, without making sure that an oncoming train is not moving along the adjacent railway track;

- crawl under carriages;

- stand or sit on the rails;

— climb on and off special steps of wagons or locomotives while the rolling stock is moving;

- to be on the inter-track when trains are moving non-stop along adjacent railway tracks;

— cross railway tracks within turnouts;

- when crossing railway tracks, step on the heads of the rails and the ends of the sleepers;

— step on electrical wires and cables;

- be on public and non-public paths in places marked with the sign “Caution! Oversized place”, as well as near these places when passing rolling stock.

2.14. A train compiler who is guilty of violating labor safety requirements and these Instructions is subject to disciplinary liability in the manner established by the regulatory documents in force.

3. OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

3.1. The train compiler's workplace is a sanitary room, room and work area (service passage routes, intertracks and the side of public and non-public tracks).

3.2. The train compiler must wear the special clothing and shoes required, a signal vest with reflective pads, and fasten all the buttons. Headgear should not impair the audibility of sound signals. There should be no foreign objects with sharp ends in your pockets. There should be no watches, rings, bracelets or other jewelry on your hands.

Check the presence and serviceability of the radio, signaling accessories and devices (brake shoes).

3.3. Familiarize yourself with the condition of the track, between the tracks and the routes of the service passage, which must be cleared of debris, foreign objects, parts of cars and materials of the upper structure of the track, and in winter, from snow and ice.

Check the functionality of shunting radio communications and rolling stock securing devices.

Receive information from the shunting dispatcher about the location and securing of rolling stock on the tracks and become familiar with the plan for the upcoming work.

3.4. Report all detected comments and violations to the shunting dispatcher, and if a danger to his life and health arises, do not begin work until such danger is eliminated.

4. OCCUPATIONAL SAFETY REQUIREMENTS DURING WORK

4.1. The train compiler, as the manager of shunting work, before the movement of cars begins, must make sure that all workers participating in the maneuvers are in their places and familiarize them with the plan and methods of performing the upcoming shunting work.

4.2. During shunting movements, the train compiler can travel on rolling stock, located on the transition platform of a freight car or locomotive platform, in the vestibule of a passenger car, on a special step of the car, while holding his hands on a special handrail.

When performing shunting work, the train designer, before starting operations using special steps, handrails and other devices, must check their serviceability.

It is prohibited for the train compiler to ride on automatic couplers, wheel set bogies, axle boxes, tank frames and other protruding parts of the car, standing on the platform or sitting on its sides.

When a shunting train is moving with the locomotive forward or a single shunting locomotive is moving, the train compiler is allowed to be on the platform or in the cabin of the shunting locomotive, and in cases where the shunting locomotive is controlled by one person (without an assistant locomotive driver) in the place of the assistant driver of the shunting locomotive, and monitor the correct position of the switches along the route and the absence of obstacles to movement.

4.3. When the shunting train moves forward with cars, the train compiler must be on the first special step of the freight car in the direction of travel, in the vestibule of the passenger car and monitor the indications of the shunting traffic lights, the position of the switches, the absence of obstacles and people on the way, signals given by workers working on the tracks, fencing signals, signal signs and signs.

In case of poor visibility of the track, malfunction or absence of a special step or handrail, with the vestibule of the passenger car closed, the train engineer must walk in the middle of the track or along the side of the road in front of the boarding cars at a safe distance, constantly keeping in touch with the driver of the shunting locomotive by radio or visually. The settling speed should not exceed 3 km/h.

When the shunting train is moving forward by wagons, in the event of a disruption in radio communication with the driver of the shunting locomotive, shunting work can be continued by hand signals under the condition of mutual visibility. The transmission of commands by the train compiler to the driver of the shunting locomotive through a third party is prohibited.

When the shunting train is moving near high platforms, in tunnels, in oversized and other dangerous places, as well as at a speed of more than 40 km/h, it is prohibited for the train operator to be on the special step of the freight car.

When shunting carriages forward through the gates of organizations on non-public tracks, guarded and unguarded crossings, as well as at oversized and dangerous places, high platforms, the train operator must stop the shunting train, get off the special step of the carriage, determine the safety of his movement, pass the crossing, gate or a dangerous place on the side of the track and from a safe place give a command to the driver of the shunting locomotive to move further.

The train engineer is prohibited from being on the special step of the car at the time of connection with the cars standing on the track.

When stopping a shunting train in front of standing cars, a high platform, a crossing, an elevated section of track, an oversized or dangerous place, it must be done at a distance of at least 5 meters from this place.

Passage of gates is permitted only after the train compiler has checked that they are securely fixed in the open position.

When a shunting train moves forward with wagons for a distance of more than 1 km, a wagon with a transition platform or an empty platform must be placed at the head of the shunting train.

4.4. The train compiler is allowed to climb onto the special step of the carriage and the locomotive, and also get off it only when the rolling stock is completely stopped.

It is prohibited to get on or off rolling stock in oversized and dangerous places, in places where bulk cargo is loaded and unloaded, within turnouts and other devices.

4.5. While the shunting train is moving, the train compiler is prohibited from entering the space between the cars, uncoupling the cars within the turnout, pedestrian deck, crossing, in places where traffic lights are installed, in oversized and dangerous places, in places where bulk cargo is loaded and unloaded.

The train compiler is prohibited from repairing the automatic coupler (uncoupling drive mechanism and other equipment) or eliminating the excess height difference between the axles of the automatic couplers of adjacent cars by placing a wedge between the centering beam and the sagging automatic coupler of the cars.

4.6. Closing the end valves of the air line, connecting and disconnecting the connecting hoses of the brake line should be carried out only after the shunting train has completely stopped and the shunting locomotive driver has been warned that the train compiler is in the space between the cars inside the track. This work may only be done with gloves.

Transmitting a command to the driver of the shunting locomotive to move is permitted only after the train compiler has left the space between the cars on the intertrack or on the side of the track.

In shunting trains with a brake line charged with compressed air, the train engineer must:

— before uncoupling the cars, first close the end valves and then disconnect the connecting hoses between the cars;

— when coupling cars, first connect the hoses and then open the end valves.

4.7. Uncoupling of standing cars must be done from the side of the car without entering the space between the cars using the release lever of the automatic coupler drive. If it is impossible to uncouple the cars, shunting work associated with uncoupling the cars is stopped until the malfunction of the automatic coupler release drive is eliminated.

The train compiler is prohibited from performing work to eliminate a malfunction of the automatic coupler release drive.

If it is impossible to couple or uncouple cars due to technical faults in the automatic coupler, employees of the car maintenance point are called in to eliminate them.

4.8. The train designer should secure the cars on the tracks only after they have come to a complete stop using brake shoes.

When securing standing cars, the brake shoe should only be grasped by the handle. Work with gloves.

When securing cars to the tracks, it is prohibited to install brake shoes:

— directly in front of the rail joint and at the rail joint;

— in front of the turnout cross;

— on the outer curved rail.

The train engineer is prohibited from placing the brake shoe by hand under moving cars. The work is carried out using a fork to lay the brake shoes on the rails.

It is prohibited to use brake shoes:

- with a burst head;

— with a warped and bent sole;

- with a burst, broken, flattened or curved toe of the sole;

— with a weakened fastening of the head with the sole;

- with or without a bent and broken handle;

- with damaged or significantly worn sides of the sole.

It is prohibited to place foreign objects under the wheel pairs instead of brake shoes to secure the cars.

4.9. When translating manually controlled switches, it is prohibited to leave the lever of the transfer mechanism in a vertical or incomplete position, and also to hold the switch counterweight (balancer) with your foot.

During shunting movements of rolling stock along turnouts, it is necessary to retreat in advance to a safe place on the side of the track or between tracks.

4.10. During shunting work, the train compiler must be located on the locomotive driver's side so that the driver can see him. In the event that when supplying cars in oversized places in places where cars are loaded (unloaded), when for some reason it becomes necessary to position the train compiler on the opposite side of the shunting locomotive driver, the train compiler moves to the opposite side, warns the shunting driver about this in advance locomotive, determines safe passage for itself and reports its location.

4.11. Shunting work in places of loading and unloading, especially bulk cargo, can only be carried out when loading and unloading operations are stopped and the dimensions of the cargo unloaded or prepared for loading are observed, i.e. at a height of up to 1200 mm, loads should be located no closer than 2 m from the outer edge of the end rail head, and at a higher height - no closer than 2.5 m.

4.12. Shunting work with loaded cars in the event that loading (unloading) is not completed must be carried out only with the permission and in the presence of a responsible representative of the organization who makes a decision on the possibility and procedure for shunting work.

4.13. When approaching an elevated track, to supply cars for unloading, the train compiler gives the driver of the shunting locomotive a command to stop. After the shunting train stops, the train compiler gets off the step of the car and, following the bottom along the elevated track, makes sure of the presence of dimensions and technical serviceability of the track, moves to a safe place, from where he gives a signal to the driver of the shunting locomotive to deposit the cars on this track. When placing cars on an elevated track, the train engineer is prohibited from being on the rolling stock and on the elevated track itself. The train compiler carefully monitors the movement of the cars and promptly gives commands to the shunting locomotive driver to reduce the speed and stop.

After installing the cars within the useful length of the unloading front and the complete stop of the train, the train compiler secures the cars on the cargo front. The carriages are secured on the elevated track using an extension ladder. Before starting work on the ladder, the train builder inspects his clothes (all items of clothing must be fastened, clothing should not restrict movement) and shoes, puts on a protective helmet and begins work.

When working with the use of a ladder, the preparer must take the following safety precautions:

— Inspect the stairs for ascent and descent. When inspecting, pay attention to the following characteristics:

1. The ladder must be of suitable length for the specific job. The dimensions of the ladder must provide the compiler with the opportunity to secure the car with brake shoes from a standing position on the step.

2. There must be a tag on the ladder indicating the date of verification of the ladder, as well as the date of the next verification.

3. All parts of the ladder must be securely fastened and have no kinks, sharp edges or nicks.

4. The lower ends of ladders must be equipped with non-slip pads or fittings with sharp tips for installation on the ground.

* If at least one of the listed points is missing, working on a ladder is not allowed.

— Before starting work, the stability of the ladder must be ensured, and by inspection and testing it must be ensured that it cannot slip out of place or be accidentally moved. Installation of an extension ladder is carried out as follows:

1. The extension ladder is installed at an angle of no more than 75° to the horizontal.

2. It is strictly forbidden to install a ladder on bulk cargo dumps, boxes, bricks, blocks. The surface under the stairs must be level.

3. The upper ends of the ladder must have a reliable stop.

— More than one person is not allowed to be on the steps of the ladder.

— When ascending or descending, the train maker must always face the ladder and hold on to it with at least one hand. Do not move beyond the ladder while working. Never climb onto a ladder from the side, on top or from another ladder, or slide down it.

— You can work on the ladder until it is convenient to reach the desired place, and then you should rearrange it.

— It is necessary to carry the ladder with the tips backwards, warning those you meet to be careful.

4.14. When performing maneuvers, the train designer must prevent the rolling stock from leaving the limit posts of the tracks (isolating joints or signals) and is obliged to place the rolling stock within their useful length.

4.15. Shunting work on non-public paths of organizations must be carried out under the supervision and personal control of a responsible employee of this organization.

4.16. When performing shunting work in the hangar, the train compiler is strictly prohibited from entering and leaving the hangar through the hangar arch. Passage must be through the service gate of the hangar.

4.17. The train compiler bears personal responsibility for strict implementation of technology and safety when performing shunting work related to the elimination of vertical and horizontal discrepancies between the centers of automatic coupling devices of cars. This work can only be done by rearranging the cars.

5. OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

5.1. Actions in the event of an accident or emergency

An emergency situation means: spontaneous movement of cars along the tracks, fire, leakage, spillage of a dangerous substance, damage to containers or rolling stock with dangerous cargo and other incidents that can lead to an accident, explosion, fire, poisoning, burns, illness of people and animals, as well as cases when wagons, containers or cargo units with dangerous cargo were in the area of rolling stock derailment, accident, crash or fire.

If spontaneous movement of cars along the tracks is detected, the train compiler must immediately notify the shunting dispatcher about this, indicating the track number and direction of movement of the cars.

The priority measures and procedure for the actions of the train operator when eliminating emergency situations with dangerous goods, including explosive materials, during their transportation by rail are established in the current Regulations.

If an emergency occurs in freight cars with dangerous goods, the train operator, who has detected obvious signs of an emergency: steam, a pungent odor, the hissing of compressed gas, a leak of dangerous cargo, must, regardless of the time of day, use any means of communication to inform the shunting dispatcher about this. The message must include a description of the nature of the emergency, the railway track number and the location of the freight car with dangerous goods on the train.

If an emergency occurs, the train operator must stop work and report the incident to the shunting dispatcher and then follow his instructions to prevent accidents or eliminate the emergency situation that has arisen.

The train engineer located nearby must immediately come to the scene of the incident upon an alarm signal and take part in providing first aid to the victim or eliminating the emergency situation.

When a fire is detected, the train designer must:

- immediately report this yourself or through the shunting dispatcher by telephone to the fire department (in this case, you must indicate the location of the fire, and also provide your last name);

— take measures to call a manager or other responsible person to the scene of the fire;

- take measures to extinguish the fire (except for cases of fire of dangerous goods) using the available primary fire extinguishing means, as well as evacuate people and material assets.

When using air-foam (powder, carbon dioxide) fire extinguishers, direct the stream of foam (powder, carbon dioxide) away from people. If foam (powder, carbon dioxide) gets on unprotected areas of the body, you must wipe it off with a handkerchief or some other cloth and rinse thoroughly with clean water.

In rooms with internal fire hydrants, it is necessary to involve two workers to extinguish a fire: one rolls out the hose from the tap to the place of the fire, the second, at the command of the one who rolls out the hose, opens the tap.

When extinguishing a fire with a fire felt, the flame should be covered so that the fire from under the felt does not fall on the worker extinguishing the fire.

When extinguishing a fire with sand, the shovel should not be raised to eye level to avoid sand getting into them.

Extinguishing burning objects located at a distance of more than 7 m from the contact network and overhead power lines that are energized is allowed with any fire extinguishers without removing the voltage. In this case, it is necessary to ensure that the stream of water or foam does not approach the contact network and other live parts at a distance of less than 2 m.

Extinguishing burning objects located at a distance of less than 2 m from the contact network is permitted only with carbon dioxide or aerosol fire extinguishers.

It is possible to extinguish burning objects with water and air-foam fire extinguishers only after the work manager or other responsible person informs that the voltage from the contact network has been removed and it is grounded.

When unenergized electrical equipment with voltage up to 1000 V catches fire, only carbon dioxide fire extinguishers should be used.

When extinguishing live electrical installations, you should not grasp the fire extinguisher socket and do not bring the socket closer than 1 meter to the electrical installation and the flame.

When a person’s clothing catches fire, it is necessary to extinguish the fire as quickly as possible, but you should not put out the flame with unprotected hands. Clothes that ignite must be quickly discarded, torn off, or extinguished by pouring water. A thick cloth, blanket, or tarpaulin can be thrown over a person wearing burning clothes, which must be removed after the flame has been extinguished.

5.2. Actions to provide first aid to victims of injury, poisoning and other health damage

5.2.1. General scheme of first aid at the scene of an incident.

Assess the situation. Determine whether there is gas contamination, the threat of explosion, fire, building collapse, electric shock, moving mechanisms, etc. Eliminate exposure of the victim to dangerous and harmful factors. The victim should be moved only in cases where it is not possible to provide assistance at the scene of the incident.

Assess the condition of the victim. Determine the condition of the victim by the presence or absence of consciousness (answers questions or not), reaction of the pupil to light, pulse in the carotid or other accessible large artery, breathing, bleeding, convulsions. Pay attention to the condition of visible mucous membranes and skin (redness, pallor, cyanosis, yellowness, the presence of wounds, burn blisters, etc.), posture (natural - unnatural). If the victim does not respond to questions and is motionless, you must immediately verify the presence of a pupillary reaction to light and the presence of a pulse in the carotid or other accessible large artery. The normal reaction of the pupil to light: when darkened, it expands, when illuminated, it narrows.

A dilated pupil and lack of constriction of the pupil when illuminated is one of the signs of cardiac arrest. If it is impossible to check the reaction of the pupil, look for a pulse in the carotid or other accessible artery.

Priority actions: if the victim has no consciousness or pulse, immediately begin restoring breathing and circulation (resuscitation). If the victim is unconscious but has a pulse, loosen clothing, turn the victim onto his stomach and clean the mouth.

Sequence of further actions: stop the bleeding; treat the wound, apply a bandage; if there are signs of fractures of the limb bones, apply transport splints; create peace for the victim; find out the circumstances of the incident, call an emergency medical team or ensure that the victim is transported to a medical facility.

6. LABOR SAFETY REQUIREMENTS AFTER COMPLETION OF WORK

6.1. At the end of the work, the train compiler must:

- hand over duty to the train compiler taking over the shift;

- tidy up your workplace;

- put signaling accessories, equipment and devices in places specially designated for them;

- take off your overalls and put them in the dressing room closet.

6.2. The train operator must inform the shunting dispatcher about all violations of the production process, labor regulations and labor safety requirements noticed during work and the measures taken to eliminate them.

Thanks to Nina for this safety instruction 😉

The issue was approved by Resolution of the State Committee for Labor of the USSR, the Secretariat of the All-Union Central Council of Trade Unions dated December 6, 1983 N 283/24-82

(As amended by the Resolutions of the State Committee for Labor of the USSR, the Secretariat of the All-Union Central Council of Trade Unions dated October 3, 1988 N 534/23-245, dated December 26, 1988 N 651/29-100, the Ministry of Labor of the Russian Federation dated November 11, 1996 N 6, dated December 19, 1996 N 18, dated December 25. 1996 N 25, dated 05/28/1997 N 26, dated 06/08/1998 N 22, dated 06/29/1998 N 26, Order of the Ministry of Health and Social Development of the Russian Federation dated 11/11/2008 N 641)

Train Compiler

§ 88. Train compiler

(as amended by Resolution of the Ministry of Labor of the Russian Federation dated December 25, 1996 N 25)

Characteristics of work. Controlling the movement of a shunting locomotive. Ensuring the correct placement and coordination of the actions of workers involved in maneuvers. Disbandment - formation of trains and groups of cars. Uncoupling and attaching cars to trains, delivering cars to loading and unloading and other specialized tracks and removing them from these tracks. Rearranging cars and trains from track to track, from depot to depot and transferring them from one station to another. Securing and fencing trains and cars standing on the tracks with brake shoes and removing them from under the cars. Participation in testing automatic train brakes. Transfer during maneuvers of non-centralized switches not serviced by switch posts on duty, or centralized switches transferred to local control. Uncoupling of cars when dissolving trains from hump yards. Regulation of the thrust speed during the dissolution of the train, depending on the driving performance and weight of the cutter. Ensuring traffic safety, safety of rolling stock and cargo. Keeping the radio station and signal accessories clean and in good working order.

Must know: job description and technical and administrative act of the train compiler; cargo transportation rules; rules and regulations on labor protection; technological process of operation of serviced stations; train formation plan; arrangement of brake shoes and rules for using them; the procedure for transferring non-centralized and centralized switches transferred to local management; general information about the structure of wagons and containers; plan, profile, specialization and capacity of the tracks, location of loading and unloading points for wagons in the serviced shunting areas; rules for storing and using radios and other means of communication.

When performing shunting work in inactive areas of industrial railway transport - 3rd category;

when performing shunting work in intense shunting areas of industrial railway transport - 4th category;

when performing shunting work in inactive shunting areas at mainline railway transport stations - category 5;

when performing shunting work in intense shunting areas at mainline railway stations of high and increased power - 6th category.

Notes 1. When performing shunting work for “one” person, a train engineer is charged one grade higher.

2. An assistant train compiler is paid one grade below the train compiler under whose supervision he works.

3.1. When performing maneuvers, the train compiler must comply with the requirements of the PTE, ISI, IDP and TPA station, which establish the procedure for performing maneuvers, and control their exact compliance by the assistant train compiler, the driver of the shunting locomotive, the attendants of the switch posts and the duty (operators) of the centralization posts.

3.2 The train designer must receive orders for shunting work only from one person in charge of shunting at the station or in a given area of the station. The train compiler must convey the received task to the assistant train compiler and other station employees participating in the maneuvers.

3.3. Before the start of maneuvers, the train designer must:

make sure that all station employees participating in maneuvers, as well as the driver of the shunting locomotive, are in their places in full;

familiarize the driver of the shunting locomotive and station workers participating in the maneuvers with the plan for performing the maneuvers. If during the execution of maneuvers the planned plan changes for some reason, then the train designer must inform all station workers participating in the maneuvers and the driver of the shunting locomotive in advance of these changes;

make sure that there are no obstacles (brake shoes and stops, foreign objects, oversized objects and other obstacles) for the movement of cars, that the automatic coupler levers are set to the normal position;

check the reliability of radio communication with the driver of the shunting locomotive, as well as with the person in charge of maneuvers at the station or in a given area of the station. If a portable radio station malfunctions during operation, the train planner must stop maneuvers, notify the driver of the shunting locomotive, as well as the person in charge of maneuvers at the station or in a given area of the station, and take measures to replace it.

When located in an area of unstable radio communication coverage established by the TPA station, the train compiler and assistant train compiler must maintain contact with the driver of the shunting locomotive using manual and audio signals. In necessary cases, other station employees must be involved to transmit signals by order of the station duty officer.

The person in charge of maneuvers at the station or in a given area of the station, the track foreman or lineman, the signaling electrician must inform the train compiler about the repair work carried out in the area of his work.

3.4. The train compiler and assistant train compiler are obliged to:

clearly and timely, in accordance with the ISI, transmit instructions and signals regarding shunting movements to the locomotive driver, switch post duty officer, duty officer or centralization post operator;

do not allow, without the permission of the station duty officer, the occupation of the station's receiving and departure tracks by rolling stock, the departure of a shunting locomotive or shunting train onto the main and receiving and departure tracks of the station, or their intersection when moving the shunting train from one shunting area to another;

monitor the timely and correct preparation of switches for shunting movements, timely and correct submission of instructions or signals by duty officers and operators of centralization posts, switch post attendants and the shunting locomotive driver;

after moving the switch, lock it to the bookmark (except for switches located on the station's marshalling tracks, on station tracks where shunting work is constantly carried out by pushes, and also equipped with articulated closures) and make sure that the point is tightly attached to the frame rail;

do not allow rolling stock to pass along the cut switch until it is inspected and repaired by a track foreman or lineman and a message is received from the station duty officer about the opening of traffic on this switch;

when performing maneuvers, choose your location in such a way as to ensure better visibility of signals and the route of movement of the shunting personnel;

when the shunting train moves forward with cars, be, as a rule, on the first special step of the car (transition platform, vestibule) in the direction of travel, and in its absence, walk along the inter-track in front of the cars being boarded, watch the traffic lights; the position of the arrows along the route, the absence of obstacles and people in the way of the station; if necessary, take measures to stop the shunting train;

When a single locomotive or shunting train is moving forward with a locomotive for a distance of more than 1 km, the train compiler or assistant train compiler is allowed to be in the locomotive driver's cabin (except when the locomotive or trains are moving within the same shunting area). In the case of servicing a locomotive by one driver, the train compiler or assistant train compiler must be in the cab on the assistant driver’s side and monitor the correct position of the switches in the route and the absence of obstacles to movement;

when performing maneuvers with large trains on curved sections of the station track or in conditions of limited visibility (fog, rain, snowstorm), take additional measures to ensure traffic safety - more often transmit signals and instructions via radio or two-way park communication, use for transmitting signals from duty switch posts , wagon speed controllers;

do not allow cars to be left without securing them with brake shoes and brake stops, as well as with cars secured below the norm established in the TPA station, regardless of the expected time of parking of these cars;

do not allow shunting trains to move (locomotive forward or wagons forward) without making sure that all wagons are coupled to each other and to the locomotive;

during push maneuvers, take timely measures to prevent the possibility of the cuts moving in the opposite direction or the cars leaving the limit column at the opposite end of the station track;

when performing push maneuvers or when pushing trains onto a hill, when the release levers, due to operating conditions, are set to the “buffer” position, after separating the release from the train, immediately return the levers to the normal position;

when a shunting locomotive or shunting train enters a station track occupied by cars to uncouple or couple other cars, as well as when compressing standing cars for uncoupling, do not allow these operations to be performed without making sure that the cars are securely secured on the side opposite the shunting locomotive;

when performing maneuvers to couple additional cars to a group of cars standing on the station track, including those secured according to the established norm, check whether the correct installation of previously laid shoes has not been disrupted as a result, and also whether these shoes are sufficient for the increased number of cars;

make sure that there are no obstacles to traffic before moving the shunting train in places where cargo is loaded and unloaded;

perform maneuvers with cars whose loading and unloading are not completed, only after agreement with the employee in charge of loading and unloading operations.

3.5. When performing maneuvers in places where work is being carried out to repair track devices, signaling systems, power supply, at crossings, near passenger platforms, on the tracks of cargo warehouses, cargo areas, fuel depots, carriage and locomotive depots, on the territory of factories, workshops, drafting and locomotive teams must exercise special vigilance, timely sound signals when the train approaches people near the station track or on the platforms, and also promptly warn about the movement of the shunting train to people working on loading, unloading, repairing the station track and cars.

When the shunting train is moving near high platforms, it is prohibited for the train compiler or assistant train compiler to be on the special step of the car on the side of the platform.

3.6. When performing maneuvers, the train designer must not allow the rolling stock to go beyond the limit posts of the station tracks (isolating joints or signals) and is obliged to place the rolling stock within their useful length. He must notify the person in charge of the maneuvers at the station or in a given area of the station, as well as the duty switch post located at the opposite end of the station tracks, who is also obliged to take the necessary measures to prevent the possibility of the rolling stock going beyond the limit column of the track ( keep an eye on the cars standing on the tracks, place brake shoes on the tracks if necessary).

3.7. When moving cars forward, the train preparer must signal the start of movement with the upcoming departure to the switches only if there is a permissive indication of the shunting traffic light or receives a signal (message) from the duty switch post about the readiness of the switches for shunting movement.

3.8. Before uncoupling the shunting locomotive from the cars or when leaving the cars on the station tracks after a push, the train designer must ensure that they stop within the boundaries of the track indicated by the limit posts and secure them from leaving in the manner established in the station's TPA.

3.9. When performing maneuvers on tracks located on slopes, in all cases, in accordance with the requirements of the TPA station, the train director must take precautions (put switches in an insulating position, place shoes under separate groups of cars), excluding the possibility of collisions of uncoupled cars with the shunting train , as well as the departure of cars to train routes or to other shunting areas.

3.10. Before the dismantling of cars from the hump, as well as before the start of push maneuvers, the train compiler and assistant train compiler are obliged to:

check the degree of clearness of the marshalling yard tracks on the side of the hump (exhaust track) and the presence of passages on them;

get acquainted with the plan for the upcoming dismantling of cars, the sequence of location of the cuts, the number of cars in each cut, the driving characteristics of the cuts and other necessary data;

in accordance with the procedure established at this station, ensure that the duty switch posts, car speed controllers, or other persons charged with the duty of switching switches or braking the releases are familiar with the nature of the upcoming disbandment of cars;

check the serviceability of the brake shoes and the special fork for releasing automatic couplers.

3.11. In the process of dismantling cars from the hump, the train compiler and assistant train compiler must:

regulate the thrust speed depending on the filling of the marshalling tracks, the conditions for the passage of cuts along the switch zone and on the sub-hill tracks, the size of the cuts, the alternation of the assignment of cuts along the tracks of the marshalling yard;

using two-way park or other types of communication, constantly inform the hump duty officer, executive post operators, wagon speed controllers, and turnout duty stations about cuts that require special care (wagons with dangerous goods, conductors (teams), people, living creatures).

3.12. Before releasing cars from the hump or before starting push maneuvers, conductors (teams) accompanying cargo or livestock must be warned by the train compiler about the upcoming maneuvers.

3.13. The train compiler and assistant train compiler should not settle and connect cars in the marshalling yard (from the side of the hump or from the opposite side of the marshalling yard tracks) without prior approval from the duty officer at the hump and the duty officer of the centralization post or switch post located at the opposite end of the station tracks. .

Before unloading, the drafting team must make sure that there are no brake shoes under the cars and that the automatic coupler release levers are in the normal position.

3.14. On the tracks of a station where there are cars with which technical or cargo operations are carried out, push maneuvers are not allowed.

In conditions of limited visibility (fog, rain, snowstorm), as well as on unlit station tracks, shunting work should be carried out with extreme caution, and, if necessary, at a reduced speed.

3.15. Maneuvers on the main tracks of the station or with their intersection, as well as with going beyond the entrance switches, can be allowed in each case only with the permission of the station duty officer (in case of dispatch centralization - the train dispatcher) with the corresponding input signals protecting the entrance to the station tracks and switches closed, on which maneuvers are carried out.

3.16. In the station's receiving and departure depots, maneuvers can be carried out only on those tracks (switches) of the station that will be indicated by the station duty officer (with dispatch centralization - the train dispatcher) when transferring the task to the train compiler for shunting work.

Departure of the shunting train to the receiving and departure tracks during maneuvers may be permitted in each individual case only with the permission of the station duty officer (in case of dispatch centralization - the train dispatcher).

3.17. If it is necessary for a shunting locomotive to enter the tracks of freight areas, coal warehouses, carriage or locomotive depots, or the train compiler must first agree on the possibility of supplying or withdrawing cars with the person in charge of maneuvers in this area. The procedure for this approval is established in the TPA station.

Related information.

Such work" Sergey Demyanov

Unsweetened life Can a diabetic work as a security guard?

How long does it take for a parcel from China to Russia from Aliexpress?

How to find a good job - a detailed guide for those who want to get their dream job!

Presentation on the topic “Acmeism