Gas odorization unit

Gas supplied to settlements must be odorized. Ethyl mercaptan (not less than 16 g per 1000 m3) or other substances can be used for gas odorization.

Gas supplied to industrial enterprises and power plants, in agreement with the consumer, may not be odorized.

If there is a centralized gas odorization unit located on the main gas pipeline, it is allowed not to provide a gas odorization unit at the GDS.

The odorization unit is installed, as a rule, at the exit of the station after the bypass line. The supply of odorant is allowed both with automatic and manual adjustment.

At the GDS it is necessary to provide containers for storing the odorant. The volume of containers should be such that they are refilled no more than once every 2 months. Filling containers and storing odorant, as well as gas odorization should be carried out in a closed way without odorant vapor release into the atmosphere or their neutralization.

Operating modes and operating parameters of the AGDS "Energy-1" Salikhovo

Control modes:

fully automatic control;

- - remote control actuators from a remote workstation of the operator;

- - remote manual and remote automatic control of actuators from the operator's panel workstation built into the ACS cabinet.

Automatic block gas distribution stations "Energia" (Fig. 1) are designed to supply individual consumers with natural, associated, oil, previously purified from heavy hydrocarbons, and artificial gas from main gas pipelines with pressure (1.2-7.5 MPa) by reducing pressure up to the specified (0.3-1.2 MPa) and maintaining it. Energia stations are operated outdoors in areas with a temperate climate at an ambient temperature of -40°C to +50°C with a relative humidity of 80% at 20°C.

The nominal capacity of the Energia-1 station for gas under the conditions in accordance with GOST 2939-63 is 10,000 m 3 / h at an inlet pressure of Pin = 7.5 MPa (75 kgf / cm 2) and P out \u003d 0.3 MPa (3 kgf / cm 2).

The maximum throughput of the station is 40,000 m 3 /h of gas at an inlet pressure Pin = 7.5 MPa (75 kgf / cm 2) and P out = 1.2 MPa (12 kgf / cm 2).

|

Indicators |

Values |

||

|

Energy-3 |

Energy-1 |

Energy-3.0 |

|

|

Bandwidth, nm 3 / h |

|||

|

Working environment pressure, MPa: |

|||

|

At the entrance |

from 1.2 to 7.5 |

||

|

At the exit |

0.3; 0.6; 0.9; 1.2 (optional) |

||

|

Working environment temperature, °С: |

|||

|

at the exit |

on demand |

||

|

Temperature, °С: |

|||

|

env. environments |

-40 to +50 |

||

|

in the GRS premises |

-40 to +50 |

at least +5 |

|

|

Number of gas outlets |

one or more, as required |

||

|

not limited |

|||

|

not limited |

|||

|

Minimum size of mechanical particles held in filters, microns |

|||

|

Number of boilers, pcs. |

2-3 (one reserve) |

||

|

Thermal power, kW: |

|||

|

heater |

235, 350 or 980 |

||

|

Gas consumption, m 3 / h: |

|||

|

To the boiler |

|||

|

For heater (Fakel-PG-5) |

|||

|

For heater (PG-10) |

|||

|

For heater (PTPG-30) |

|||

|

For heater (PGA-200) |

|||

|

Coolant pressure, MPa: |

|||

|

With boilers |

|||

|

From the heating network |

|||

|

In the heater |

atmospheric |

||

|

Heat carrier temperature, °С |

|||

|

Odorizer type |

automatic with discrete feed |

||

|

Overall dimensions, mm |

Weight, kg |

||

|

Reduction block |

|||

|

Switch block |

|||

|

Odorization block |

|||

|

Instrumentation and A block (option) |

|||

|

Gas heater PG-10 |

Description of the technological scheme

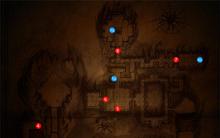

The technological scheme of the AGDS "Energy-1" Salikhovo is shown in Figure 1.4.

High-pressure gas entering the GDS inlet passes through ball valve No. 1 (see Fig. 1.4) to the gas heater PTPG-15M, where it is heated to prevent the precipitation of crystal hydrates.

Heating is carried out in the coil by the radiation of the burner and the heat of the exhaust gases.

Heated high-pressure gas through taps No. 7,6 enters the reduction unit combined with the purification unit. The reduction knot consists of two reducing threads: working and reserve.

In the reduction unit, the fuel gas is reduced to feed the burners from Pout. up to 100-200 mm. water. Art.

From the gas reduction unit low pressure passes to the locking point.

After the metering unit, the gas enters the odorization unit, and then to the switching unit. The gas enters the switching unit through the inlet valve No. 12 and is ejected through the outlet thread onto the candle.

The prepared gas is supplied to the consumer with an outlet pressure of 0.6 MPa.

Figure 1.4 - Technological scheme of the AGDS "Energy-1" Salikhovo

Description:

At present, the cities of Russia have developed gas supply systems for industry and the social sector. Gas is supplied to the cities from the distribution system of Gazprom with a pressure of 1.2 MPa, while consumers need gas with a pressure of 0.1; 0.3; 0.6 MPa. To meet the requirements of consumers for gas pressure, gas pressure reducing stations and points (GDS, GRP) are located within the city.

Generation of electricity and "cold" without burning fuel

Technical data of power range units

Approbation in operation of a pilot electric refrigeration complex at the Yuzhnaya GDS will open up significant prospects for the development of this area of fuel economy and, as a result, a reduction in the environmental impact on the environment.

Thus, according to tentative estimates, it is possible to generate more than 250 million kWh of electricity annually at the Moscow GDS alone (without the Mosenergo GDS), using PEGA, and at the same time use about 200 million kWh of "cold" in refrigerators with an area of up to 70 thousand m 2, which will prevent the burning of more than 270 thousand tons of fuel equivalent at the CHPP. tons per year with the corresponding environmental effect.

The payback of capital investments in the electric refrigeration complex will not exceed two years. Its service life is 60 years.

The cost of generated 1 kWh of energy will not exceed 6-7 kopecks. After the introduction of two or three electric refrigeration complexes, further implementation of the program can be carried out at the expense of self-financing from profits.

It seems expedient to develop and implement in a short time an addition to the Moscow energy saving program for 2004 and subsequent years, which provides for the widespread introduction of electric refrigeration complexes at the Moscow GDS. This will make it possible to efficiently use the existing considerable energy resource of “waste” gas pressure energy at the GDS for environmentally friendly generation of electricity and “cold” using it in refrigerators. For this, the necessary conditions have already been created and there is a serially produced complete equipment.

Production and industrial technologies

The system for delivering products from gas fields to consumers is a single technological chain. From the fields, gas flows through the gas collection point through the field collector to the gas treatment plant, where the gas is dried, cleaned from mechanical impurities, carbon dioxide and hydrogen sulfide.

INTRODUCTION 3

1 Classification of gas distribution stations 4

1.1 Stations individual design 4

1.2 Block-packed GDS 5

1.3 Automatic GDS 6

2 Technological schemes and the principle of operation of the GDS different types 8

2.1 Technological scheme and principle of operation of GDS of individual design 8

2.2 Technological scheme and principle of operation of BK_GRS 10

2.3 Technological scheme and principle of operation of AGDS 12

3 Typical equipment at GDS 14

3.1 Industrial fittings 15

3.2 Gas pressure regulators 17

3.3 Gas filters 19

3.4 Safety valves 21

3.5 Gas meters 23

3.6 Gas odorisers 23

3.7 Gas heaters 24

CONCLUSION 26

LIST OF USED SOURCES 27

INTRODUCTION

In industry, along with the use of artificial gases, natural gas is increasingly being used. In our country, gas is supplied over long distances through main gas pipelines of large diameters, which are a complex system of structures.

The system for delivering products from gas fields to consumers is a single technological chain. From the fields, gas flows through the gas collection point through the field collector to the gas treatment plant, where the gas is dried, cleaned from mechanical impurities, carbon dioxide and hydrogen sulfide. Then the gas enters the main compressor station and the main gas pipeline.

Gas from main gas pipelines is supplied to urban, rural and industrial systems gas supply through gas distribution stations, which are the end sections of the main gas pipeline and are, as it were, the border between city and main gas pipelines.

A gas distribution station (GDS) is a set of installations and technical equipment, measuring and auxiliary systems of gas distribution and regulation of its pressure. Each SRS has its own purpose and functions. The main purpose of the gas distribution station is to supply gas to consumers from main and field gas pipelines. The main consumers of gas are:

Objects of gas and oil fields (own needs);

Objects of compressor stations (own needs);

Objects of small, medium and large settlements, cities;

power plants;

Industrial enterprises.

The gas distribution station performs a number of specific functions. Firstly, it cleans the gas from mechanical impurities and condensate. Secondly, it reduces the gas to a given pressure and maintains it with a given accuracy. Thirdly, it measures and records the gas flow. Also, the gas distribution station carries out gas odorization before it is supplied to the consumer and gas is supplied to the consumer, bypassing the main blocks of the gas distribution station, in accordance with the requirement of GOST 5542-2014.

The station is a complex and responsible energy (technological) object of increased danger. The technological equipment of the GDS is subject to increased requirements for the reliability and safety of energy supply to consumers with gas, industrial safety as an explosion and fire hazardous industrial facility.

1 Classification of gas distribution stations

Depending on the performance, design, number of outlet manifolds, gas distribution stations are conditionally divided into three large groups: GDS small (1.0-50.0 thousand m 3 /h), medium (50.0-160.0 thousand m 3 /h) and high productivity (160.0-1000.0 thousand m 3 /h or more).

Also, HRS are classified according to the design feature (Figure 1). They are divided into the following types: stations of individual design, block-packed GDS (BK-GRS) and automatic GDS (AGDS).

GDS

AGRS-1/3, AGRS-1, AGRS-3, AGRS-10

Energy-1M, Energy-2

Tashkent-1, Tashkent-2

Source

With two outlets

BK-GRS-II-70

BK-GRS-II-130

BK-GRS-II-160

With one outlet

BK-GRS-I-30

BK-GRS-I-80

BK-GRS I -150

Automatic

Individual design

Block-complete

Figure 1 - Classification of gas distribution stations

- Stations of individual design

GDS design is carried out by specialized design organizations in accordance with current rules and regulations process design and sections of SNiP.

Stations of individual design are those stations that are located near large settlements and in capital buildings. The advantage of these stations is the improvement of service conditions for technological equipment and living conditions for service personnel.

- Block-complete GDS

BK-GRS can greatly reduce the cost and time for construction. The main design of the gas distribution station is a block-box made of prefabricated three-layer panels.

The largest block-box weight is 12 tons. The degree of fire resistance - Sha. Estimated outdoor temperature - 40° C , for the northern version - 45° C . Delivery of all elements of the block-complete GDS is carried out by the manufacturer. At the installation site, the blocks are connected by gas pipelines and cables, equipped with auxiliary equipment (lightning rod, blowing candle, spotlights, burglar alarm, etc.) and a fence, forming a complete complex.

BK-GRS are intended for gas supply of cities, towns and industrial enterprises from main gas pipelines with gas pressure of 12-55 kgf/cm 2 and maintaining outlet pressure 3, 6, 12 kgf/cm 2 .

Block-complete gas distribution stations can be with one or two output lines to consumers (Figures 2 and 3). Known BK-GRS six sizes. With one outlet to the consumer, three standard sizes - BK-GRS- I -30, BK-GRS-I-80, BK-GRS- I -150. As well as three standard sizes with two outputs to the consumer - BK-GRS- II -70, BK-GRS-II-130 and BK-GRS-II-160.

Figure 2 - Structural diagram of GDS with one consumer

Figure 3 - Structural diagram of GDS with two consumers

BK-GRS of all sizes are used in Russia and the CIS countries, but all of them are subject to reconstruction at the installation site according to individual projects, as they have significant design flaws in the units for cleaning, heating, reducing and accounting for gas.

- Automatic GDS

Automatic GDS contain basically the same technological units as GDS of an individual or block-complete type. At the assembly site, they are also equipped with auxiliary equipment and a fence, like BK-GRS. AGRS, unlike other types of GDS, operate using unmanned technology.

These stations are designed to reduce high pressure (55 kgf/cm 2 ) natural, associated petroleum, artificial gases that do not contain aggressive impurities, to a predetermined low (3-12 kgf / cm 2 ), maintaining it with a given accuracy of ±10%, as well as for preparing gas before supplying it to the consumer in accordance with the requirements of GOST 5542-2014.

All AGRS are designed for outdoor operation in areas with seismicity up to 7 points on the Richter scale, with a temperate climate, at an ambient temperature of minus 40 to 50 ° C with a relative humidity of 95% at 35°C.

During the operation of the AGDS, significant design flaws are revealed, which in their majority are reduced to the following:

Failure of gas pressure regulators due to condensate in the process of gas reduction in the form of ice flakes and sticking of the regulator valve by them;

Failure in winter time instrumentation due to low temperatures in instrumentation and signaling units heated by lighting lamps.

- Technological schemes and the principle of operation of GDS of different types

2.1 Technological scheme and principle of operation of GDS of individual design

There are various technological schemes of GDS. Consider the technological scheme on the example of GDS-5 (Figure 4).

Gas from the main gas pipeline GM1 enters under pressure through the insulating flange FI1, the inlet valve KV to the reduction unit of the first stage UR1. The reduction node contains input CL1 and output CL2 collectors. Gas from the outlet manifold enters the working line, consisting of three lines L1-L3 connected in parallel with shut-off valves K1-K3 and gate valves K4-K6. With the help of valves K4-K6, manual reduction of gas is carried out at a pressure of 3 MPa. There is also a bypass line with a K7 valve. The reduction unit has a reserve thread, which has the same equipment as the working thread: L4-L6 lines, K8-K10 shut-off valves, K11-K13 gate valves and K14 bypass valve. The main K17 and reserve K18 three-way valves with safety valves KP1-KP4 are installed in the outlet manifold, which protect the manifold from excessive pressure increase.

From the outlet manifold of the first stage of reduction, the gas is directed through an odorization unit with a working tank E1, an insulating flange FI2 into the main gas pipeline GM2 and into the reduction unit of the second stage UR2. Through the main gas pipeline GM2, gas can be supplied to a large consumer, for example, a gas processing plant, or vice versa, gas is received from this plant and fed to the second stage reduction unit.

The gas enters the reduction unit of the second stage through the switching unit UPR, containing valves K61-K65, the three-way valve K66 with safety valves KP5, KP6 and the purification unit UO, consisting of inlet KL3, outlet KL4 collectors, inlet K19, K21, K23, K25, K27 valves with bypass valves K29-K33 of smaller nominal diameter, outlet valves K20, K22, K24, K26, K28, gas separators GS1-GS5 with mesh nozzles. There is also a bypass valve K34 of the cleaning unit. The inlet KL5 and outlet KL6 collectors of the reduction unit are connected by reduction lines L7-L14, equipped with inlet shut-off valves K35-K42, regulators RD1RD8, outlet shut-off valves K43-K50. To reduce and maintain a constant gas pressure at the outlet, devices such as RDU and LORD-150 are used as regulators RD1-RD8.

After leaving the reduction unit, the gas enters the inlet manifold KL7 of the metering unit UU, which is connected to the outlet manifold KL8 by gas flow measurement lines L15-L19.

Figure 4 - Technological scheme of GDS-5. Individual project.

These lines are equipped with measuring diaphragms D1-D5, as well as inlet K51-K55 and outlet K56-K60 stopcocks. From the outlet collector KL8, the gas, passing through the valves K62, K64 of the switching unit, the odorization unit UO2 with the working tank E2 and the insulating flange FI3, enters the gas distribution pipeline GR. The working tanks of the odorizing plants are periodically replenished from the underground storage tank E3 of the odorant.

2.2 Technological scheme and principle of operation of BK_GRS

As an example, let's consider the technological scheme of a block-complete gas distribution station of the brand BK-GRS- I -30 (Figure 5).

The GRS works as follows. High-pressure gas enters the BPR switching unit, consisting of valves K1, K2, on the inlet and outlet gas pipelines, a bypass line L1 with valves K3, K4, a three-way valve K5, safety valves KP1, KP2, and a discharge line L2 to a candle with a K6 valve from the high pressure line. From the BPR unit, the gas is directed to the BOC cleaning unit, which consists of two multicyclone dust collectors МЦП1, МЦП2, shut-off valves K7-K10, bypass line L3 with valve K11. Valves K7-K11 allow you to turn off one or two multicyclones for cleaning and repair work, while passing the gas through one of the multicyclones or bypass line L3. Multicyclones are designed to clean gas from mechanical impurities and condensate. Drainage of condensate from the dust collectors is automated with the help of level regulators and valves with a membrane drive.

The purified gas enters the BPD heating unit. Heating of gas is carried out by fire heater of PGA-10 type.

From the heating unit, the gas enters the BR reduction unit, which consists of two lines L4, L5: working and reserve. Both lines have the same equipment and their functions change periodically. Valves K12, K13 with pneumatic actuator, gas pressure regulators RD1 and RD2 type RD-100-64 and valves K14, K15 with manual drive at the outlet are installed on the reduction lines. In the event of a failure of the working line, the Zashchita-2 system is triggered by an increase in gas pressure at the outlet of the reduction unit, with which it is connected via the L6 impulse line, which can be shut off with the K16 valve.

From the BR reduction unit, gas enters the gas metering unit (flow measurement), consisting of two lines L7, L8: working and reserve. The gas flow rate is measured by chamber diaphragms D1 and D2 of the DK-100 type and recorded by differential pressure gauges-flowmeters DR. Cranes K17-K20 allow switching between the working and reserve lines L7, L8.

Figure 5 – Technological scheme of gas distribution station of brand BK-GRS- I-30

The gas after the metering unit passes through the switching unit and enters the BOD odorization unit, where a universal odorizer of the UOG-1 type is installed. The block contains consumable PC1, underground tank PC2, level gauge U, viewing window CO and valves for controlling the operation of the block.

After leaving the odorization unit, the gas enters the network to consumers.

Insulating flanges FI1, FI2 are installed on the inlet and outlet gas pipelines of all standard sizes of BK-GRS, preventing the penetration of stray currents into the station equipment.

The alarm system ensures the supply of an undecrypted signal to the DO and the dispatcher's console of the health facility in case of violations of the station.

2.3 Technological scheme and principle of operation of AGDS

As an example, let's consider the technological scheme of an automatic gas distribution station of the AGRS-10 brand (Figure 6) .

AGRS-10 works according to the following scheme. The high pressure gas enters the switching unit, which consists of gas pipelines, a bypass line with two valves, a safety valve assembly with a three-way cock, manual plug valves and pressure gauges. When gas is supplied to the consumer through the bypass line, gas reduction is carried out manually, using a valve.

From the switching unit, the gas is directed to a fired gas heater of the PG-10 type. The heated gas enters the purification unit, where it is purified from mechanical impurities with the help of filters, and then it is sent to the reduction unit. All components of the reduction unit, as well as the heating unit, are located in a metal cabinet with three double doors that provide free access to all units and controls.

In the reduction unit there are two reducing lines (working and reserve) with a pressure regulator of the RDU-50 type, plug valves with both manual and pneumatic drives, a multiplier and control units for them, a relief valve, a shield with electrocontact pressure gauges, an automation and protection shield , filter driers for command gas. From the reduction unit, the gas enters the gas metering unit by chamber diaphragms of the DK-200 type, the gas flow is recorded by differential pressure gauges-flowmeters. Then the gas enters the odorization unit, where an odorizer of the UOG-1 type is installed.

The AGDS is equipped with a remote alarm system to control the operation of the station's main components. Control over the mode of the blocks is carried out by sensors connected cable lines with a remote alarm transmitter unit installed in the instrumentation unit.

1 - manual input valve; 2 – gas heater; 3 - crane with pneumatic actuator; 4 - filter; 5 – gas pressure regulator; 6.12 - cranes with manual drive; 7 - accounting block; 8 – gas odorizer; 9 – container for odorant; 10 - safety valve; 11 - three-way valve; 13 - cabinet gas control unit; 14 - insulating flange; 15 - bypass line.

Figure 6 - Technological scheme of GDS brand AGRS-10

- Typical equipment at GDS

The gas distribution station includes:

Knots:

a) station switching;

b) gas cleaning;

c) prevention of hydrate formation;

d) gas reduction;

e) gas heating;

f) commercial measurement of gas flow;

g) gas odorization (if necessary);

h) autonomous power supply;

i) gas withdrawal for own needs;

Systems:

a) control and automation;

b) communications and telemechanics;

c) electric lighting, lightning protection, protection against static electricity;

d) electrochemical protection;

e) heating and ventilation;

f) burglar alarm;

g) control of gas contamination.

The GDS switching unit is designed to switch the high-pressure gas flow from automatic to manual pressure control along the bypass line, as well as to prevent pressure build-up in the gas supply line using safety valves.

The GDS gas purification unit is designed to prevent the ingress of mechanical (solid and liquid) impurities into process and gas control equipment and means of control and automation.

The hydrate formation prevention unit is designed to prevent freezing of fittings and the formation of crystalline hydrates in gas pipelines and fittings.

The gas reduction unit is designed to reduce and automatically maintain the specified pressure of the supplied gas.

The gas metering unit is designed to account for the amount of gas consumption using various flow meters and meters.

The gas odorization unit is designed to add substances with a sharp unpleasant odor (odorants) to the gas. This allows timely detection of gas leaks by smell without special equipment.

These nodes and systems consist of equipment that performs the functions intended for the elements that make up the GDS.

- Industrial fittings

Industrial fittings - a device installed on pipelines, units, vessels and designed to control (shutdown, control, discharge, distribution, mixing, phase distribution) the flow of working media (gaseous, liquid, gas-liquid, powder, suspension, etc.) by changing passage area.

There are a number of state standards that regulate the requirements for fittings. In particular, the main parameters of cranes must be viewed in accordance with GOST 21345-2005.

Industrial fittings are characterized by two main parameters: nominal diameter (nominal size) and nominal (nominal) pressure. Under conditional pass DN or D understand the parameter used for pipeline systems as a characteristic of the attached parts (GOST 28338-89). Nominal pressure PN or Py – the highest overpressure at a working medium temperature of 20 ° C , which ensures the specified service life of fittings and pipeline connections having certain dimensions, justified by the calculation of strength for selected materials and characteristics, their strength at a temperature of 20 ° C. The values and designations of nominal pressures must correspond to those specified in accordance with GOST 26349-84.

Industrial fittings can be classified according to several criteria.

Functional purpose (view).

Shut-off. Designed for full coverage (or full opening) the flow of the working medium, depending on the requirements of the technological regime.

Regulating (reducing). Designed to regulate the parameters of the working medium by changing its flow rate. It includes: pressure regulators (Figure 7), control valves, liquid level regulators, throttling valves, etc.

Safety. Designed for automatic protection of equipment and pipelines from inadmissible pressure by dumping excess working medium. These include: safety valves, impulse safety devices, diaphragm rupture devices, bypass valves.

Protective. Designed for automatic protection of equipment and pipelines from unacceptable or unforeseen changes in the parameters or direction of the flow of the working medium and to turn off the flow without resetting the working medium from technological system. This includes non-return and shut-off valves.

Phase separation. Designed for automatic separation of working environments depending on their phase and state. These include steam traps, oil separators, gas separators, air separators.

Figure 7 - Pressure regulator device

construct types.

Gate valves. Their working body moves back and forth perpendicular to the flow of the working medium. It is mainly used as a shut-off valve.

Valves (valves) (Figure 8). Shut-off or regulating working body they move reciprocating parallel to the axis of the flow of the working medium.

Cranes. Their locking or regulating working body has the form of a body of revolution or part thereof, rotates around its axis, arbitrarily located in relation to the flow of the working medium.

shutters. The locking or regulating body they have, as a rule, has the shape of a disk and rotates around an axis that is not its own.

Figure 8 - Three-way valve (valve)

- Gas pressure regulators

The hydraulic mode of operation of the gas distribution system is controlled by pressure regulators. The gas pressure regulator (RD) (Figure 9) is a device for lowering (reducing) the gas pressure and maintaining the outlet pressure within the specified limits, regardless of changes in the inlet pressure and gas flow, which is achieved by automatically changing the degree of opening of the regulating body of the regulator, as a result of which also automatically changes the hydraulic resistance to the passing gas flow.

RD is a combination of the following components:

A sensor that continuously monitors the current value of the controlled variable and sends a signal to the control device;

A setting device that generates a signal for the set value of the controlled variable (required output pressure) and also transmits it to the control device;

A control device that performs an algebraic summation of the current and set values of the controlled variable, and a command signal enters the actuator;

An actuator that converts a command signal into a regulatory action, and into the corresponding movement of the regulatory body due to the energy of the working environment.

1 - control valve; 2 – direct action control regulator; 3.4 - adjustable throttle; 5 - throttle.

Figure 9 - Gas pressure regulator RDBK1P

Due to the fact that the gas pressure regulator is designed to maintain a constant pressure at a given point in the gas network, it is always necessary to consider the automatic control system as a whole - “the regulator and the object of regulation (gas network)”.

The correct selection of the pressure regulator should ensure the stability of the "regulator - gas network" system, i.e. its ability to return to its original state after the cessation of the disturbance.

Depending on the maintained pressure (the location of the controlled point in the gas pipeline), RDs are divided into regulators “before themselves” and “after themselves”.

Based on the control law underlying the operation, pressure regulators are astatic (working out the integral control law), static (working out the proportional control law) and isodromic (working out the proportional-integral control law).

In statistical RD, the amount of change in the control opening is directly proportional to the change in gas flow in the network and inversely proportional to the change in outlet pressure. An example of a static RD is regulators with a spring-loaded outlet pressure adjuster.

RD with an integral control law in the event of a change in gas flow creates an oscillatory mode, due to the control process itself. When the gas flow rate is changed, the difference between the original and set outlet pressures increases until the amount of gas passing through the regulator is less than the new flow rate and reaches its maximum when these values are compared. At this moment, the opening speed of the control hole is maximum. But the regulator does not stop at this, but continues to open the hole, passing more gas than required, and the outlet pressure, accordingly, also increases. The result is a series of fluctuations around a certain average value, at which a constant mode (as in the case of a static regulator) will never be reached.

Representatives of astatic regulators are RD with a pneumatic output pressure adjuster, and undamped self-oscillations of some types of pilot RD in certain transient operating modes can be considered a typical example of such a process.

An isodromic regulator (with elastic feedback), when the regulated pressure deviates, will first move the regulated body by an amount proportional to the deviation, but if the pressure does not reach the set value, then the regulating body will move until the pressure reaches the set value. Such a controller combines the accuracy of integral and the speed of proportional control. Representatives of isodromic RD are "straight-through" regulators[ 9 ] .

- Gas filters

Gas filters are designed to clean gas from dust, rust, resinous substances and other solid particles. High-quality gas purification increases the tightness of locking devices and increases the overhaul time of these devices by reducing the wear of sealing surfaces. This reduces wear and increases the accuracy of flow meters (meters and measuring orifices), which are especially sensitive to erosion. The right choice of filters and their qualified operation are one of the most important measures to ensure the reliable and safe operation of the gas supply system.

According to the direction of gas movement through the filter element, all filters can be divided into direct-flow and rotary, according to the design - into linear and angular, according to the material of the housing and the method of its manufacture - into cast iron (or aluminum) cast and steel welded.

When developing and selecting filters, the filter material is especially important, which must be chemically resistant to gas, provide the required degree of purification and not be destroyed under the influence of the working environment and in the process of periodic filter cleaning.

According to which filter material is selected for the filter, they are divided into mesh (Figure 10) and hair (Figure 11). In mesh, a woven metal mesh is used, and in hair, cassettes stuffed with nylon thread (or pressed horsehair) and impregnated with viscin oil.

1 - body; 2 - cassette; 3 - grid; 5 - cover.

Figure 10 - Mesh filter type FS

1 - body; 2 - breaker sheet; 3 - cassette; 4 - perforated sheet; 5 - filter element; 6 - cover; 7 - fittings; 8 - flange.

Figure 11 - Hair type FG filter

Mesh filters, especially two-layer ones, are characterized by increased fineness and cleaning intensity. During operation, as the mesh becomes clogged, the fineness of filtration increases while reducing bandwidth filter. In hair filters, on the contrary, during operation, the filtering ability decreases due to the entrainment of particles of the filter material by the gas flow and during periodic cleaning by shaking.

To ensure a sufficient degree of gas purification without entrainment of solid particles and filter material, the gas flow rate is limited and is characterized by the maximum allowable pressure drop across the mesh or filter cassette.

For mesh filters, the maximum allowable pressure drop should not exceed 5000 Pa, for hair filters - 10000 Pa. In the filter before operation or after cleaning and washing, this difference should be 2000–2500 Pa for mesh filters, and 4000–5000 Pa for hair filters. The design of the filters has fittings for connecting devices, with the help of which the magnitude of the pressure drop across the filter element is determined.

- Safety valves

Increasing or decreasing the gas pressure after the pressure regulator in excess of the specified limits can lead to an emergency. With an excessive increase in gas pressure, flame separation from the burners and the appearance of an explosive mixture in the working volume of gas-using equipment, leakage, gas leakage in the joints of gas pipelines and fittings, failure of instrumentation, etc. are possible. A significant decrease in gas pressure can lead to slippage of the flame into the burner or extinction of the flame, which, if the gas supply is not turned off, will cause the formation of an explosive gas-air mixture in the furnaces and gas ducts of the units and in the premises of gasified buildings.

A common cause of a sharp decrease in pressure for any network may be a violation of the tightness of gas pipelines and fittings, and, consequently, a gas leak.

To prevent an unacceptable increase or decrease in pressure, fast-acting safety shut-off valves (PZK) (Figure 12) and safety relief valves (Figure 13) (PSK) are installed.

PZK are designed to automatically stop the gas supply to consumers in the event of an increase or decrease in pressure above the specified limits; they are installed after the pressure regulators. PZK work at "emergency situations", therefore their spontaneous inclusion is inadmissible. Before manually turning on the slam-shut device, it is necessary to detect and eliminate malfunctions, and also make sure that the shut-off devices in front of all gas-using devices and units are closed. If, according to the conditions of production, a break in the gas supply is unacceptable, then instead of a slam-shut device, an alarm system should be provided to alert the maintenance personnel.

Housing - 1; Adapter flange - 2; Cover - 3; Membrane - 4; Large spring - 5; Cork - 6; Small spring - 7; Stock - 8; Valve - 9; Guide post - 10; Plate - 11; Fork - 12; Rotary shaft - 13; Lever - 14; Anchor lever - 15; Rocker - 16; Hammer - 17.

Figure 12 - Shut-off safety valve

PSK are designed to discharge into the atmosphere a certain excess volume of gas from the gas pipeline after the pressure regulator in order to prevent pressure from rising above the set value; they are installed after the pressure regulator on the outlet pipeline.

1 - body; 2 - cover; 3 - valve with a guide; 4 - spring; 5 - adjusting screw; 6 - membrane; 7 - plate; 8 - spring plate; 9 - cover.

Figure 13 - Safety relief valve

In the presence of a flow meter (gas meter), PSK must be installed after the meter. After reducing the controlled pressure to a predetermined value, the PSK must be hermetically sealed.

- Gas consumption meters

Metering devices of the highest accuracy should be installed on the GDS.

If gas transportation volumes exceed 200 million m 3 per year, to improve the reliability and reliability of gas volume measurements, it is recommended to use duplicate measuring instruments (SI). Duplicate MIs should not affect the operation of the main MIs. It is recommended that the primary and backup metering systems use different methods for measuring gas flow and quantity.

At measurement nodes with a maximum gas volume flow of more than 100 m 3 /h, at any overpressure or volume flow range from 16 m 3 /h up to 100 m 3 / h, at an overpressure of more than 0.005 MPa, the measurement of gas volume is carried out only using calculators or gas volume correctors.

At an excess pressure of not more than 0.005 MPa and a volume flow of not more than 100 m 3 /h it is allowed to use flow converters with automatic correction of gas volume only by its temperature.

The composition of the measuring instruments and auxiliary devices, on the basis of which the gas metering unit is made, is determined by:

The measurement method used and the requirements of the measurement procedure governing the measurement;

Appointment of the metering unit;

A given gas flow rate and the range of its change;

Pressure and gas quality indicators, taking into account gas extraction modes;

The need to include metering units in automated systems commercial gas metering.

In general, gas metering includes:

Flow transducer for measuring the volume and flow of gas;

Measuring pipelines;

Gas quality preparation facilities;

Gas quality analyzers;

A complex of technical means of automation, including processing, storage and transmission of information.

3.6 Gas odorisers

The gas odorizer is intended for dosed supply of an odorant (a mixture of natural mercaptans) into the gas flow at the outlet line of a gas distribution station with an operating pressure of up to 1.2 MPa (12 kgf/cm2) in order to impart a characteristic odor to the gas.

The gas odorizer is used as part of the GDS and provides:

Dosed supply of odorant to the pipeline;

Control of the injected odorant dose and automatic correction of the odorant consumption depending on the current gas consumption;

Automatic accounting of the total consumption of the odorant;

Display of the following information on the display screen of the odorizer control unit (CUO):

a) the level of odorant in the working tank;

b) the current value of the hourly gas flow received from the flow meter;

c) odorizer operating time;

d) the accumulated total value of the odorant consumption since the launch of the ODDC;

e) emergency and warning signals.

Communication with various upper-level systems according to an agreed protocol.

Odorizers are designed for outdoor operation in areas with seismicity up to 9 points with a temperate and cold climate in conditions normalized for UHL performance, placement category 1 according to GOST 15150-69. The location of the odorizer control unit is determined by the project for linking the ODDK or GDS in an explosion-proof zone, in a heated room.

3.7 Gas heaters

Gas heaters are designed for heating and automatically maintaining the set temperature of gas before its throttling at gas distribution stations. The gas is heated to ensure the reliability of the process equipment. Working environment: the gaseous environments which are not containing aggressive impurity.

Thermal power produced Russian enterprises heaters exceeds the actual needs of the GDS. As a result, 75% of heaters operate with a load of less than 50%, 51% with a load of less than 30%, 15% with a load of less than 10%. Of more than 150 modifications of direct heating gas heaters and with an intermediate heat carrier, produced by the domestic industry, direct heating gas heaters PGA-5, PGA-10, PGA-100 satisfy in terms of thermal power.

PGA heaters with an intermediate heat carrier are designed to heat natural, associated and petroleum gas to a predetermined temperature and can be operated both as part of gas distribution stations and autonomously. As a rule, PGA heaters are equipped with modern system automation designed for autonomous and remote control.

The main advantage of PGA heaters is that the gas is heated through an intermediate coolant, which can be diethylene glycol or coolant. Due to this, PHA heaters have a higher reliability and safety of operation compared to heaters that heat fuel gas directly with gas.

The main advantages of PGA heaters are their high reliability and safety.

CONCLUSION

The gas distribution station (GDS) is the main facility in the system of main gas pipelines, the function of which is to reduce the gas pressure in the pipeline and prepare it for the consumer. Modern gas distribution stations are complex, highly automated and energy-intensive facilities. The operation of gas pipelines can occur under various modes, the change of which occurs when the options for switching on the units are changed. In this case, the problem arises of choosing the most expedient modes corresponding to the optimal loading of the gas pipeline.

With the development of electronic computer science automated control of the GDS became possible. Currently, both domestic automation systems and foreign instrumentation, automation and telemechanics systems are widely used at GDS facilities.

The territory of the gas distribution station must be fenced and equipped with a security alarm. The gas distribution station should be located outside the prospective development of the settlement in accordance with building codes.

Maintenance of a gas distribution station should be carried out on the basis of the "Rules technical operation gas distribution stations of main gas pipelines.

In most cases, GDS were built in the middle 1970s years. In general, the service life of the Russian gas transmission system is approaching half a century: 14% of gas pipelines have worked for more than 33 years and require immediate replacement, another 20% are approaching this age, 37% were built 10-20 years ago and another 29% are younger than 10 years.

LIST OF USED SOURCES

1. GOST 5542-2014. Combustible natural gases for industrial and domestic purposes. – M.: 2015. – 12 p.

2. Kantyukov R.A. Compressor and gas distribution stations. / R.A. Kantyukov, V.A. Maksimov, M.B. Khadiev - Kazan: KSU im. IN AND. Ulyanov-Lenin, 2005. - 204p.

3. Danilov A.A. gas distribution stations. / Danilov A.A., Petrov A.I. - St. Petersburg: Nedra, 1997. - 240 p.

4. Golyanov A.I. Gas networks and gas storage facilities: A textbook for universities. / A.I. Golyanov - Ufa: LLC "Publishing House of Scientific and Technical Literature "Monograph"", 2004. - 303p.

5. GOST 21345-2005. Ball, cone and cylindrical valves for nominal pressure not more than PN 250. General specifications. – M.: 2008. – 16.

6. GOST 28338-89. Pipe connections and fittings. Conditional passages (nominal dimensions). Rows. - M.: 2005. - 4s.

7. GOST 26349-84. Pipe connections and fittings. Pressures are nominal (conditional). Rows. - M.: 1996. - 5s.

8. Directory. Industrial gas equipment. 6th edition, revised and enlarged. / Ed. E.A. Karyakina - Saratov: Research Center for Industrial Gas Equipment "Gazovik", 2013. - 1280s.

9. Website. Industrial gas equipment. Company "Gazovik" [Electronic resource] - Access mode: http :// gazovik-gaz. en

10. Website. Purpose, scope and operating conditions of the odorizer [Electronic resource] - Access mode: http://odorizator.ru

11. GOST 15151-69. Machines, devices and others technical products. Versions for different climatic regions. Categories, operating conditions, storage and transportation in terms of the impact of climatic factors external environment. – M.: 2008. – 72p.

12. LLC Firm "SGPA". Modern equipment for gas distribution stations. Gas heater with intermediate coolant PGPT-3. // Sphere oil and gas. - 2010. - No. 3. - p. 48-49.

13. Rules for the technical operation of gas distribution stations of main gas pipelines. M.: - Nedra, 1982.

14. Website. Industrial safety expertise and technical diagnostics of gas distribution stations [Electronic resource] - Access mode:http://www.strategnk.ru/section/130

As well as other works that may interest you |

|||

| 76792. | Axillary fossa | 184.1KB | |

| The axillary cavity is the axillary fossa, the space between the lateral chest and the shoulder. The walls of the cavity The anterior wall is formed by the subclavian pectoralis major and minor muscles covered by the sternoclavicular fascia. The superior clavicular pectoralis is located between the clavicle and the upper edge of the pectoralis minor muscle. The middle pectoralis muscle corresponds to the pectoralis minor, starting from the IIIY ribs and inserting on the coracoid process of the scapula. | |||

| 76793. | Venous plexuses and anastomoses | 179.96KB | |

| In many organs, organ venous plexuses arise: pharyngeal thyroid vesical rectal and others. Three large veins: the superior inferior vena cava and portal each form their own venous system. Venous connections between branches of the same vein, that is, within the same system, are considered intrasystemic. Cavacaval anastomoses in the anterior abdominal wall are formed by the tributaries of the superior vena cava: the superior epigastric thoracic-epigastric vein and the tributaries of the inferior vena cava: the inferior epigastric and superficial epigastric. At the back of the chest... | |||

| 76794. | placental circulation | 180.17KB | |

| umbiliclis reaches the gate of the liver and divides into a portal branch that flows into the portal vein and a larger venous duct ductus venosus that flows into the hepatic or inferior vena cava. Therefore, a small part of the blood passes through the entire system of the portal vein of the liver as a fetal hematopoietic organ and flows into the inferior vena cava through the hepatic veins. The umbilical vein, after ligation, overgrows in the navel and is located in the round ligament of the liver, flowing into the portal vein, which is used to administer drugs and diagnostics through it in case of ... | |||

| 76795. | Heart - development, structure, topography | 182.81KB | |

| After fusion of the septa, a secondary interatrial foramen oval is formed, as the cranial part of the septum breaks through. The left foramen and mitral bicuspid valve lie at the level of the III costal cartilage; the right and tricuspid valve lie above the IV cartilage near the sternum. The aortic orifice and its semilunar valves are located posterior to the left edge of the sternum at the level of the 3rd intercostal space; opening of the pulmonary trunk with semilunar valves above the third right costal cartilage at the right edge of the sternum. Right atrium atrium dexter... | |||

| 76796. | The structure of the myocardium | 183.83KB | |

| conduction system of the heart. In the atria and ventricles, a different number of layers are formed with an unequal arrangement and direction of the muscle fibers of contractile cardiomyocytes, which start from the soft connective tissue skeleton of the heart. In the contractile myocardium of the ventricles, there are: a common surface layer with obliquely oriented fibers starting from the fibrous rings and going to the apex of the heart, where they form a vortex curl and smoothly pass into the inner layer; the middle layer of circular fibers, which is... | |||

| 76797. | Vessels and nerves of the heart | 180.54KB | |

| They surround the base of the heart with a crown, which is why they are often called coronal. The left coronary artery passes between the beginning of the pulmonary trunk and the left ear and the anterior interventricular branch descends to the apex of the heart and the circumflex branch along the coronary sulcus and posterior surface. The most pronounced and permanent anastomoses are: in the upper part of the anterior wall of the right ventricle; in the anterior wall of the left ventricle along the left edge; at the apex of the heart in the posterior interventricular sulcus and interventricular septum; in the walls of the atria. | |||

| 76798. | Vessels of the great circle | 180.76KB | |

| The aorta divides throughout its entire length into parietal and visceral branches and ends with a bifurcation into the common iliac arteries at the level of the IVVth lumbar vertebrae. From its parietal and visceral branches, extra and intraorganic arteries arise, which usually approach the organs from the medial side using the shortest paths. In terms of parenchymal organs: the lungs, the liver, the spleen, the kidney, the arteries branch in accordance with the division into parts of the sector, segments and smaller parts up to structural and functional units ... | |||

| 76799. | femoral canal | 180.44KB | |

| The deep ring of the femoral canal is located in the medial part of the vascular lacuna under the inguinal ligament and is limited: from above by the inguinal ligament at the place of its attachment to the pubic tubercle and symphysis; from below by the pubic crest and the pectinate ligament covering it; medially lacunar ligament filling the inner corner of the vascular lacunae; laterally by the wall of the femoral vein. In practice, a well-palpable inguinal ligament acts as an important clinical and anatomical landmark that makes it possible to distinguish a femoral hernia from an inguinal hernia, since the femoral ... | |||

| 76800. | Medial and posterior muscles and fascia of the thigh | 180.94KB | |

| The medial femoral muscle group is well developed due to upright posture and performs hip adduction, therefore it is mainly equipped with adductor muscles. The long adductor muscle begins as a thick tendon from the pubic bone between the crest and symphysis. The muscle lies borderline with the medial wide of the quadriceps femoris. A short adductor muscle with an origin from the body and the lower branch of the pubic bone attached to the upper part of the thorny line of the femur; adducts and flexes the hip. | |||

Federal State Budgetary Educational Institution

higher professional education

"Ufa State Oil Technical University"

Department of Automation of Technological Processes and Productions

Graduation project

Gas distribution station automation

Sterlitamak Linear Production Department of the main gas pipeline

Student gr. AG 07-01 A.G. Askarova

Supervisor

Consultants:

cand. tech. Sciences, Assoc. S.V. Svetlakova

cand. tech. Sciences, Assoc. A.A. Gilyazov

Diploma project 109 pages, 26 figures, 26 tables, 19 references, 1 appendix.

GAS DISTRIBUTION STATION, OVERPRESSURE SENSOR, PRESSURE CONVERSION METHODS, METRAN-100-Vn-DI, ANALYSIS OF PRESSURE SENSORS

The object of the study is the automation of the gas distribution station of the Sterlitamak linear production department of the main gas pipeline "Energy - 1".

In the course of the study, an analysis was made of the existing level of GDS automation, and the need to replace overpressure sensors was substantiated.

The aim of the work is to modernize the automation system of the gas distribution station "Energy-1".

As a result of the study, it was recommended for use at the gas distribution station for regulation and measurement of the excess pressure sensor "EJX430A" by Yokogawa. The algorithm of the program for the logical control of the transition of the GDS to the bypass mode has been compiled.

Technical and economic characteristics confirm the feasibility of introducing a modern pressure sensor.

There is no implementation.

The effectiveness of the project lies in the high efficiency of the proposed replacement, since the devices being introduced are much better in terms of metrological characteristics.

Definitions, symbols, abbreviations

Introduction

1.1 Purpose and composition of the SRS

1.4 Switching unit

1.5 Gas cleaning unit

1.6 Gas reduction unit

1.7 Gas heating unit

1.8 Gas odorization unit

1.9 Gas metering unit

2. Patent study

2.2 Search regulations

2.3 Search results

2.4 Analysis of search results

3.1 Scope of automation

3.2 Information and measuring complex "Magistral-2

3.3 Pressure conversion methods

4. Modernization of the GDS automation system

4.1 Problem statement and problem analysis

4.2 Rationale for sensor selection

4.3 Sensor selection

4.4 Algorithm for switching the GDS to bypass mode

5. Occupational health and safety

5.1 Analysis of potential hazards and industrial hazards at GDS

5.2 Measures to ensure safe and harmless working conditions at the GDS

5.3 Calculation of lightning protection of GDS

6. Evaluation economic efficiency modernization of the automation system of GDS Energia-1

6.1 Criteria for evaluating economic efficiency

6.2 Justification of the commercial effectiveness of the project

Conclusion

List of sources used

Definitions, symbols and abbreviations

GDS - gas distribution station

LPU - linear production management

MG - main gas pipeline

AWP - automated workplace

ACS - automated control system

RD - pressure regulators

BPG - gas heating unit

APCS - automated process control systems

KIP - instrumentation

TCA - technical means of automation

SCADA - Supervisory Control And Data Acquisition

TR - strain gauge

SNS - technology "silicon on sapphire"

CNC - technology "silicon on silicon"

ADC - analog-to-digital converter

DAC - digital-to-analog converter

PAZ - emergency protection

NPV - net present value

ID - profitability index

GNI - internal rate of return

CO - payback period

Introduction

Gas distribution stations are designed to supply gas from main and field gas pipelines to settlements, enterprises and other large consumers. It is required to supply gas to the consumer in a given quantity and under a certain pressure, with the necessary degree of purification, heating and odorization of gas (if necessary). The control system must be complex enough to take into account all the variety of static and dynamic characteristics of the plant.

With the help of automatic control of the gas distribution station, the highest productivity is ensured with the least expenditure of energy resources, cost reduction and improvement in product quality, the number of maintenance personnel is reduced, the reliability and durability of equipment is increased, working conditions and safety measures are improved.

The purpose of this graduation project is the technical re-equipment, improvement of the existing automation system of the gas distribution station "Energy-1", the introduction of modern automation tools.

The objectives of the graduation project are:

Studying the technology of gas preparation for supply to the consumer;

Analysis of the automation system of the GDS "Energia-1";

Modernization of the existing GDS automation system;

Drawing up an algorithm for the program of logical control of the automatic transition of the GDS to the bypass mode.

During the work, materials from the Sterlitamak LPU of GazpromtransgazUfa LLC were used.

1. Technological scheme of GDS and its characteristics

1.1 Purpose and composition of the SRS

The basic technological process of the enterprise Sterlitamak LPU MG OOO GazpromtransgazUfa is the transportation of gas in the south of the Republic of Bashkortostan and its supply to the GDS, which supply gas to the consumer.

The station is a complex and responsible technological object of increased danger. The technological equipment and automation equipment of gas distribution stations are subject to increased requirements for the reliability and safety of energy supply to consumers with gas, as well as for industrial safety, as for explosive and fire hazardous industrial facilities.

Gas distribution stations are designed to supply gas from main and field gas pipelines to the following consumers:

Objects of gas and oil fields (for own needs);

Objects of gas compressor stations;

Objects of small and medium settlements;

power plants;

Industrial, municipal enterprises and settlements.

GDS provide:

Gas purification from mechanical impurities and condensate;

Gas heating;

Reduction of the set pressure and constant maintenance of it with a certain accuracy;

Gas flow measurement with multi-day registration;

Odorization of gas in proportion to its consumption before supply to the consumer.

The GRS includes:

1) station switching;

2) gas purification;

3) prevention of hydrate formation;

4) gas reduction;

5) gas heating;

6) commercial measurement of gas flow;

7) gas odorization;

8) autonomous power supply;

Systems:

1) control and automation;

2) communications and telemechanics;

3) electric lighting, lightning protection, protection against static electricity;

4) electrochemical protection;

5) heating and ventilation;

6) burglar alarm;

7) control of gas contamination.

1.2 Description of the technological scheme

The technological scheme of the automated gas distribution station "Energy-1" is shown in Figure 1.1.

High-pressure gas entering the GDS inlet passes through ball valve No. 1 to the PTPG-15M gas heater, where it is heated to prevent precipitation of crystalline hydrates.

Heating is carried out in the coil by the radiation of the burner and the heat of the exhaust gases.

The heated high-pressure gas through taps No. 6, 7 enters further into one of the reduction lines in the reduction unit, combined with the purification unit, where the pressure is reduced to a predetermined value and the process gas is cleaned from mechanical particles and liquid. The reduction knot consists of two reducing threads: working and reserve.

Figure 1.1 - Technological scheme of AGDS "Energy-1"

In the reduction unit, the fuel gas is reduced to feed the burners from Pout to 0.1-0.2 Pa.

From the reduction unit, low-pressure gas passes to the metering unit.

After the metering unit, the gas enters the odorization unit, and then to the switching unit. The gas enters the switching unit through the inlet valve No. 12 and is ejected through the outlet thread onto the candle.

The prepared gas is supplied to the consumer with Pout = 0.6 MPa.

1.3 Operating modes and operating parameters of the automated GDS "Energy-1"

GRS operate both autonomously and in the mode of constant presence of service personnel. In any case, the current state of the station is controlled by the LPU MG, on whose territory the station is located.

For continuous monitoring and control (including automatic) of the state of all local subsystems of the GDS, it is necessary to have a local automated control system for the GDS, connected with the system of dispatch control and management of the entire network of the GDS from the LPU MG.

There are 3 control modes available on the automated GDS:

Fully automatic;

Remote control of actuators from a remote operator workstation;

Remote manual and remote automatic control of actuators from a panel operator workstation built into the ACS cabinet.

Automatic block gas distribution stations "Energia-1" are designed to supply individual consumers with natural, associated, oil, previously purified from heavy hydrocarbons, and artificial gas from main gas pipelines with pressure (1.2--7.5 MPa) by reducing the pressure to a predetermined ( 0.3--1.2 MPa) and maintain it. Energia stations are operated outdoors in areas with a temperate climate at an ambient temperature of minus 40 °C to +50 °C with a relative humidity of 80% at 20 °C.

The nominal throughput of the Energia-1 station is 10,000 m3/h at an inlet pressure Рin=7.5 MPa and Рout=0.3 MPa.

The maximum capacity of the station is 40,000 m3/h of gas at inlet pressure Pin=7.5 MPa and Pout=1.2 MPa. Table 1.1 shows the operating parameters of the automated GDS "Energy-1".

Table 1.1 - Operating parameters of the automated gas distribution station "Energy-1"

|

Indicators |

Values |

|

|

Throughput, m3/h |

||

|

Working environment pressure, MPa: At the entrance At the exit |

0,3; 0,6; 0,9; 1,2 |

|

|

Temperature, °С: Environment In the premises of the GDS |

||

|

Number of gas outlets |

||

|

Minimum size of mechanical particles held in filters, microns |

||

|

Thermal power of the heater, kW |

||

|

Gas consumption, m3/h: For heater "PG-10" For heater "PTPG-30" For the PGA-200 heater |

||

|

Coolant pressure in the heater, MPa |

atmospheric |

|

|

Heat carrier temperature, °С |

||

|

Odorizer type |

Automatic with discrete feed |

|

|

Overall dimensions L/W/H, mm Reduction block Switch block Odorization block Instrumentation and A block |

||

|

Weight, kg Reduction block Switch block Odorization block Instrumentation and A block |

1.4 Switching unit

The switching unit is designed to switch the gas flow from one line to another line of the gas pipeline, to ensure trouble-free and uninterrupted operation of the GDS in cases of repair or hot and gas hazardous work. The bypass line connecting the inlet and outlet gas pipelines of the GDS is equipped with temperature and pressure measuring devices, as well as a shut-off valve and a control valve.

The switching unit is designed to protect the consumer's gas pipeline system from possible high gas pressure. Also for supplying gas to the consumer, bypassing the gas distribution station, through the bypass line using manual gas pressure control during repair and maintenance work of the station.

In the GDS switching unit, the following should be provided:

Cranes with pneumatic actuator on gas pipelines of inlet and outlet;

Safety valves with switching three-way cocks on each outlet gas pipeline (it is allowed to replace in the absence of a three-way cock with two manual ones with blocking, excluding simultaneous shutdown of the safety valves) and a candle for gas discharge;

Isolating devices on the inlet and outlet gas pipelines to maintain the cathodic protection potential with separate protection of on-site communications of the gas distribution station and external gas pipelines;

A candle at the GDS inlet for emergency gas discharge from process pipelines;

A bypass line connecting the gas pipelines of the inlet and outlet of the gas distribution station, providing short-term gas supply to the consumer, bypassing the gas distribution station.

The GDS bypass line is designed for short-term gas supply for the period of inspection, prevention, replacement and repair of equipment. The bypass line must be equipped with two taps. The first is a shut-off valve, which is located along the gas flow and the second is a throttling valve-regulator. In the absence of a valve-regulator, it is allowed to use a valve with a manual drive.

The switching unit consists of two valves (No. 1 on the inlet and No. 2 outlet gas pipelines), a bypass line and safety valves.

Through the safety valve, the gas (through the high-pressure inlet pipeline with a pressure of 5.4 MPa) enters the switching unit, which includes inlet and outlet pipelines with shutoff valves. Ball valves with a lever or pneumohydraulic drive with local control using an electro-pneumatic control unit are used as shut-off valves. A candle valve is also provided for discharging gas into the atmosphere.

Ball valves serve as a shut-off device on main gas pipelines, at gas collection and treatment points, at compressor stations, at gas distribution stations and can be operated in areas with a temperate and cold climate.

The design of the valves provides for operation at the following ambient temperature:

In areas with a temperate climate from minus 45 to + 50 ° С;

In areas with a cold climate from minus 60 to + 40 ° С;

while the relative humidity of the ambient air can be up to 98% at a temperature of plus 30 °C.

The transported medium through the valve is natural gas, with nominal pressure up to 16.0 MPa and temperature from minus 45 to + 80 °C. The content of mechanical impurities in the gas - up to 10 mg/nm3, particle size - up to 1 mm, moisture and condensate - up to 1200 mg/nm3. The use of taps to regulate the gas flow is prohibited.

In the absence of pressure or in the case when it is not enough to close the valve with a pneumohydraulic actuator, the shutdown is carried out by a manual hydraulic pump. The position of the spool switch pump handle must correspond to the marking: “O” - opening the tap by the pump, “3” - closing by the pump or “D” - remote control, which is indicated on the pump cover.

Cranes provide the passage of cleaning devices through them. The design of the valves provides the possibility of a forced supply of sealing lubricant to the sealing zone of the annular seats and the spindle in case of loss of tightness. The system for supplying sealing lubricant to the annular seats of underground valves has a double blocking with check valves: one valve in the fitting, and the second on the valve body in the boss. The fittings are of a single design, provide quick connection of the stuffing device adapter.

Annular sealing valve seats provide tightness at pressures from 0.1 to 1.1 MPa.

Pin and Pout from the switching unit is controlled by pressure sensors. To protect low consumer networks, two spring-loaded safety valves are installed on the outlet pipeline, one of which is working, the other is reserve. Valves of the "PPPC" type (spring full-lift safety valve) are used. During operation, the valves should be tested for operation once a month, and in winter - once every 10 days, with an entry in the operational log. Valves of this type are equipped with a lever for forced opening and control purge of the gas pipeline. Depending on the setting pressure, safety valves are equipped with replaceable springs.

For the possibility of revision and adjustment of spring-loaded safety valves without disconnecting consumers, a three-way valve of the KTS types is installed between pipelines and valves. The three-way valve of the KTS type is always open to one of the safety valves.

The setting of spring safety valves depends on the requirements of gas consumers, but in general this value does not exceed 12% of the nominal value of the outlet pressure.

Figure 1.2 shows the gas switching unit.

Figure 1.2 - Photograph of the gas switching unit

In the switching unit, there is an opportunity to purge the inlet and outlet pipelines through a spark plug valve, the pipeline of which is located outside the GDS site.

The switching unit must be located at a distance of at least 10 m from buildings, structures or process equipment installed in an open area.

1.5 Gas cleaning unit

The gas purification unit at the gas distribution station helps prevent mechanical impurities and condensate from entering the equipment, process pipelines, control and automation devices of the station and gas consumers.

To clean the gas at the GDS, dust and moisture trapping devices of various designs are used, which provide gas preparation in accordance with the current regulatory documents for operation. The main requirement for the gas purification unit is the automatic removal of condensate into collection tanks, from where it is removed from the territory of the GDS as it accumulates.

The gas purification unit must provide such a degree of gas purification that the concentration of admixture of solid particles with a size of 10 microns should not exceed 0.3 mg/kg, and the moisture content should not exceed the values corresponding to the state of gas saturation.

After the switching unit, through the inlet valves, the gas enters the gas purification unit, which is combined with the reduction unit.

The gas purification unit mainly uses oil dust collectors, viscin filters and multicyclone separators. Oil dust collectors are used at stations with high hourly productivity.

An underground tank is installed at the GDS to collect and remove moisture and condensate with automatic control systems for the level and amount of condensate in tanks and dust collectors. The inlet and outlet pressure of each dust collector is monitored by pressure sensors.

To clean the gas at the gas distribution station, dust and moisture trapping devices should be used to ensure gas preparation for the stable operation of the gas distribution station equipment and the consumer.

Filters 1 and 2, the location of which is presented in section 3, are designed to purify gas from mechanical impurities, as well as to remove condensate. To signal the level in the filter reservoir, sensors of the lower, upper and emergency levels are installed. When the units are designed with automatic sludge discharge, the design includes a valve with a pneumatic actuator and a shut-off valve that operates at the border of the liquid and gaseous fractions.

The gas purification unit incorporates filter-separators or a block of filter-separators designed to purify gas from solid particles and condensed moisture. The degree of purification is 10 microns, the efficiency is 99.99%. The cleaning products from the storage tank of the filter-separators are automatically discharged into the condensate collection vessel.

The capacity of the tank should be determined from the condition of draining impurities within 10 days.

Tanks must be designed for the maximum possible pressure and equipped with a liquid level indicator.

In order to exclude emissions of condensate and odorant vapors into the atmosphere, it is necessary to apply measures for their disposal.

Technological process collection of gas cleaning products from tanks should exclude the possibility of spillage and ingress of liquid onto the ground.

Figure 1.3 shows the gas purification unit.

Figure 1.3 - Photo of the gas cleaning unit

1.6 Gas reduction unit

The reduction unit is designed to reduce high inlet gas pressure Pin = 7.5 MPa to low outlet pressure Pout = 0.3 MPa and automatically maintain the set pressure at the outlet of the reduction unit, as well as to protect the consumer's gas pipeline from unacceptable pressure increase.

Since the reduction unit is combined with the purification unit, here the gas is dried, mechanical impurities are removed and condensate is removed.

The gas reduction unit is one of the most important functions at the GDS. Here, the high pressure gas is reduced to a predetermined value and automatically maintained at a certain level. The reduction unit consists of gas control equipment, shut-off valves, reduction lines, a protective automation system and an alarm. In the diagrams of the reduction node, the following are used:

Steel control fittings for nominal pressure of 6.3 MPa;

Valves regulating indirect action;

RD direct action.

For pressure control, direct-acting RD or analog-controlled regulators are used. Direct-acting regulators are faster and more reliable, since an intermediate link is eliminated - communication channels and a control device, moreover, they do not require additional energy, since they work due to the energy of the gas flow. Domestic manufacturers produce regulators that provide pressure regulation with an accuracy of 2.5%.

On gas distribution stations of large capacity, control valves are more often used, since they allow you to quickly change the regulated pressure at the valve outlet and have big choice sizes.

As command devices for valves of indirect action, proportional regulators of the RD type are used. There are two types of control valves: normally open (pressure is supplied to the top of the membrane) and normally closed (under the membrane).

All control valves consist of a control body (valve) and a diaphragm actuator connected via a stem to the valve spool. Setting the outlet gas pressure in all types of control valves is carried out by loading the valve stem with a spring.

The reduction unit is designed to lower the inlet pressure from 5.4 MPa to 0.6 MPa and supply gas through a low pressure pipeline to the linear networks of gas consumers.

In the GDS reduction unit, the number of reducing lines should be taken at least two (one reserve). It is allowed to use three reduction lines of equal productivity (one reserve).

In the reduction unit (Figure 1.4), if necessary, it is allowed to provide a line of low flow rates for operation in the initial period of operation of the GDS.

Figure 1.4 - Photograph of the reduction node

Reducing lines within one reduction unit must be equipped with the same type of shut-off and control valves. Gas reduction lines must be equipped with discharge candles.

Reducing lines must have automatic protection against deviation from operating parameters and automatic switching on of the reserve.

1.7 Gas heating unit

The gas heating unit or GDS is designed for indirect heating of gas to a predetermined temperature; it is used as part of a gas distribution station to prevent hydrate formation during gas reduction and maintain the gas temperature at the outlet of the gas distribution station at a given value, as well as to provide heat carrier for space heating systems or other possible heat consumers.

BPG are designed for operation in areas with a temperate and moderately cold climate, as well as in areas with a cold climate.

The standard size of the heating unit as part of the GDS should be determined from the conditions for ensuring the required gas temperature at the outlet of the GDS, the normal operation of the station equipment and the exclusion of its icing. In the case of using LPG in the heating circuit, additional heat load must be taken into account.

The gas is heated in a shell-and-tube heat exchanger by means of an intermediate heat carrier heated in a hot water boiler. The heat carrier, depending on the thermal power of the unit, is heated up to 95 °C and is fed to the shell-and-tube heat exchanger, where heat is transferred to the heated body (gas), then the cooled heat carrier from the return heat pipe with a temperature of up to 95 °C is fed to the inlet of the hot water boiler. If there is an additional heating circuit, the coolant is taken from the return heat pipe.

Structurally, the gas heating unit consists of a boiler room unit and a heat exchanger unit.

The equipment of these blocks is placed in a box hermetically divided into two compartments: a boiler room compartment (category D) and a heat exchanger compartment (category B-1a). The box is made of panels, has a removable roof, which allows you to quickly install and repair heavy and large-sized equipment. The stability of the block-box to seismic loads is up to 9 points. The compactness of the unit and full factory readiness allow for transportation, installation and commissioning in the shortest possible time.

The required thermal power is provided by two hot water boilers in the boiler room to increase the reliability of the unit. In case of failure of one boiler, the second one can ensure the plant's operability in emergency mode.

Circulation pumps are installed at the inlet of hot water boilers and operate under the control of the pump control and protection device in the operating time distribution mode. If one pump fails, a serviceable pump ensures 100% performance. To protect the system from exceeding the internal hydraulic pressure, the boilers are equipped with safety discharge devices (discharge is carried out into the expansion tank).

The power supply of the BPG is carried out from the industrial network 220 V/50 Hz, or 380 V/50 Hz. Power is supplied through an input cabinet equipped with circuit breakers. The inlet cabinet is installed in the boiler compartment.

1.8 Gas odorization unit