In logistics, transport plays a significant role, connecting individual economic regions, companies, enterprises and firms. By moving material resources and finished products from the sphere of production to the sphere of production or personal consumption, transport thereby participates in the process of reproduction of material goods.

The main decisions in logistics are related to the demand for transport services. They include planning and routing of transport, type and size of transport, tariffs for services.

Logistics models, according to American experts, in addition to the location of firms, the choice of vehicles for transportation, inventory management and routing, should also include such tasks as creating statistical models, multiple company goals, multiple products, multi-echelon requests. American economists believe that there is no universal model that can take into account all variables, all situations and all possible scenarios. Such a universal model will never be developed and it is useless to strive for it.

When solving short-term problems, one of the most important logistics techniques is vehicle routing. Despite the large amount of research, not everything in this area is well researched. It is interesting to study the trade-offs between the availability of product stocks from suppliers and consumers, its placement and transportation.

A promising area of research is the development effective methods optimization of interaction (human-machine). Such methods can simultaneously use a person's intuition, his understanding of problems and the ability of a computer to quickly process information.

The purpose of this work is the formation of skills in the organization of transportation of products.

To achieve this goal, it is necessary to solve the following tasks:

study transport products and their features;

explore organizational structure and distribution management;

analyze the routes of movement of vehicles and calculate its performance indicators using the example of " business game».

1 ESSENCE OF TRANSPORT, PRODUCTS AND QUALITY OF SERVICE

Transport is a branch of material production, as it has its own products. This product is a move. Unlike other branches of material production, during transportation, the production process continues within the circulation process and for the circulation process. It should be noted that the processes of production and consumption in transport are not separated in time. Products in transport are consumed in the production process, as its beneficial effect, and not as a thing.

By the nature of its products, transport differs from other branches of material production. Firstly, the product does not have a material form, but at the same time it is material in nature, since material resources are spent in the process of movement: rolling stock and service facilities wear out, the labor of transport workers is used, etc.

Since transport products do not have the form of a thing, the second feature is that they cannot be accumulated in a warehouse. This feature is of great practical value. If at enterprises and firms the creation of certain stocks of products contributes to the satisfaction of production as needed, then transport must have reserves of throughput and wire capacity in transportation under any conditions.

The third feature is that transport products are additional transport costs that are associated with the movement of industrial products. They are referred to distribution costs, which emphasizes the dual nature of these costs. On the one hand, they are necessary, since transportation is a continuous production process, and on the other hand, it should be taken into account that the transport of a new product does not create. Therefore, it is necessary to use it in such a way that the transport costs are the lowest, other things. equal conditions to use the mode of transport that is most efficient for the given type of product and distance.

Transport products are sold and bought, i.e. acts as a commodity, and therefore has a use-value and value. The use value of transport products is their ability to meet the needs for the transportation of various types of goods. The use value of transport products can be expressed by their delivery to the consumer exactly on time (on a certain day and hour) and in a certain quantity. Many foreign firms claim that they value the possibility of organizing just-in-time delivery more than the trademark of the supplier company.

The cost of production, or the cost of transportation, is determined by the amount necessary costs transport companies or firms or cargo transportation. When buying transport products, consumers pay these costs in the form of tariffs and freight rates, which are at the same time a monetary expression of the cost of transport products.

It is important not only to calculate individual indicators of the logistics system, but also to ensure the maximum high level customer service quality.

The quality of transport products is the timely delivery of products to the consumer in a certain quantity and at a certain time.

The tool for the quality of transport products should be an agreed schedule that would link all participants in the organization of the logistics system when promoting products.

2 ROAD TRANSPORT, ITS TYPES AND ROUTES

The material and technical base of road transport consists of rolling stock (cars, tractors, trailers and semi-trailers), a motor transport company and roads.

The expediency of using rolling stock of one type or another is determined by its operational and technical qualities and specific operating conditions. The operational and technical qualities of a car include its dimensions and weight, cross-country ability, stability and maneuverability, mobility, dynamic qualities and economy.

Rolling stock efficiency indicators can be cost, productivity, energy intensity, material consumption, etc.

2.1 Types of vehicles

Road transport is distinguished by the following features:

branch - transportation of goods of industry, construction, Agriculture, trade, utilities, postal;

the size of the consignment - bulk and small batch transportation. Bulk is the transportation of a large volume of homogeneous cargo;

territorial - urban, suburban, intra-district, inter-district, intercity and international shipping;

way of implementation: local - carried out by one motor transport enterprise; direct communication - several motor transport organizations are involved in the transportation; mixed traffic - transportation by two or more modes of transport. One of the forms of intermodal transport is combined. In combined transport, the cargo is transferred from one mode of transport to another without reloading. This is achieved, for example, by using special semi-trailers-contrailers transported from railway platforms, on river and sea vessels;

development time - permanent, seasonal and temporary transportation. Permanent transportation is carried out throughout the year, seasonal - only at certain times of the year, temporary are episodic;

organizational features - centralized and decentralized. With centralized transportation, motor transport enterprises act as organizers of the delivery of goods to the recipient and carry out this process themselves. With decentralized transportation, each consignee independently ensures the delivery of goods.

2.2 Vehicle routes

Vehicles move along routes. The route of movement - the path of the car when performing transportation.

Transportation routing is the most perfect way to organize the material flow of goods from the consumer's warehouse. This system has a significant impact on the efficient use of road transport.

Creating a route allows you to accurately determine the optimal volume of transportation of goods from the warehouse, the number of cars carrying out these transportations, which helps to reduce the downtime of cars for loading and unloading, the efficient use of rolling stock and the release of significant material consumers from the spheres of circulation. At the same time, transportation routing allows you to increase the productivity of the car while reducing the number of vehicles entering the warehouse. In conditions when routes are created, delivery dates are determined and they are observed, consumer inventories can be reduced by 1.5 - 2 times.

The main elements of the route: the length of the route - the path traveled by cars from the start to the end point of the route; vehicle turnover - a complete cycle of movement, i.e. movement from start to finish.

Traffic routes can be pendulum and ring. With a pendulum route, the route of the car between two cargo points is repeatedly repeated. Ring route - the route of the car along closed loop, connecting several consumers (suppliers). Varieties of ring routes are delivery, prefabricated and prefabricated routes. A distribution route is a route in which products are loaded from one supplier and delivered to several consumers. An assembly route is a route of movement when products are received from several suppliers and delivered to one consumer. A collection and delivery route is a combination of delivery and collection routes.

One of the tasks in the logistics system is the development of a strategy and a logistics concept, building a model of transport service for consumers and firms. This strategy is based on the calculation of rational transportation routes and the compilation of optimal schedules (schedules) for the delivery of products to the consumer, i.e. answers questions about when, how much and at what time the goods should be delivered. Options for organizing the movement of a car can be: a pendulum route with a return empty run or a delivery route for the transportation of small-lot cargo to consumers.

In practice, when planning the operation of vehicles on a pendular route with a reverse idle run, only one rule is followed: the last point of unloading vehicles should be as close as possible to the fleet. This common-sense recommendation is considered to provide the minimum empty mileage.

Logistics system can also deal with the attachment of suppliers to the consumer. This may be if the supplier has regional warehouses located in different economic regions, and a certain number of consumers

3 DEVELOPMENT OF ROUTES OF VEHICLE TRANSPORT ON THE EXAMPLE OF "BUSINESS GAME"

Table 3.1

Store order sheet

| store number |

Monday |

||

Table 3.1 shows the number of boxes scheduled for delivery on Monday. The total number of boxes ordered is 1440.

Conventions: P - products;

M - detergents;

N - drinks.

Table 3.2

Calculation of route parameters

| route number |

store number |

Order size, boxes |

|||

| R=114 boxes |

|||||

| T=39*3+57+60=3h 54m |

|||||

| M=28-27-25-24-26-23 |

|||||

| R=118 boxes |

|||||

| T=43*3+30+59+90=5h 08m |

|||||

| R=114 boxes |

|||||

| T=36*3+57+75=4h 00m |

|||||

| M=1-29-30-3-4-2 |

|||||

| R=118 boxes |

|||||

| T=39*3+59+30+90=4h 56m |

|||||

| M=1-29-30-3-4-2 |

|||||

| R=102 boxes |

|||||

| T=39*3+51+90=4h 18m |

|||||

| R= 98 boxes |

|||||

| T=30+48*3+60=3h 54m |

|||||

| R= 120 boxes |

|||||

| T=54+30*3+60=3h 30m |

|||||

| R= 116 boxes |

|||||

| T=30+39*3+58+60=4h 35m |

Continuation of the table. 3.2

| route number |

store number |

Order size, boxes |

Route calculation results |

||

| R=box |

|||||

| T= 48+60+37*3= 3h 39m |

|||||

| R= 116 boxes |

|||||

| T= 30+57+60+44*3= 4h 39m |

|||||

| M= 19-17-18-20-22 |

|||||

| R= 116 boxes |

|||||

| T= 58+75+42*3= 4h 19m |

|||||

| M= 19-18-20-22-21 |

|||||

| R= 102 boxes |

|||||

| T= 30+51+75+34*3= 4h 18m |

|||||

| M= 14-10-12-11-9 |

|||||

| R= 112 boxes |

|||||

| T= 42*3+75+56= 4h 17m |

|||||

Table 3.2 shows that 13 routes were completed. At the same time, the plan for 1440 boxes was fulfilled.

Symbols: M - way around shops along the route;

P - the amount of transported cargo, boxes;

L is the length of the route, km;

T - the time of the car on the route, min.

Table 3.3

Transport schedule

| Machine No. |

First trip |

Second trip |

staleness car- |

|||||

| route number |

Departure time from warehouse |

Arrival at the warehouse |

route number |

Departure time from warehouse |

Arrival at the warehouse |

|||

Table 3.4

Calculation of the total costs for the delivery of goods

| Machine No. |

Ownership of the car (own or hired) |

Numbers of routes completed per day |

The amount of transported cargo |

Mileage per day, km |

Car fee |

|||

| Mileage fee (conditionally variable costs) |

Semi-fixed costs for the maintenance and use of the car |

Overtime pay (5 rubles per minute) |

Penalty for incomplete use of vehicle capacity (less than 90 boxes) |

Penalty for incomplete use of the car by time (less than 6 hours) |

Security costs for the transport of drinks by hired transport |

Total fee for using the car |

||

Tables 3.3 and 3.4 show these quantities own cars and hired. At the same time, all our own transport and one hired car were involved. It was also paid for overtime to drivers of their own transport - 960 rubles and a fine for incomplete use of a hired car - 500 rubles.

Table 3.5

Order Fulfillment Plan

| Monday |

||||

| route number |

store number |

Order size, boxes |

||

Continuation of the table. 3.5

| Monday |

||||

| route number |

store number |

Order size, boxes |

||

Table 3.6

Analysis of the results of goods delivery planning

| Index |

Calculation formula |

Monday |

| Total costs for the delivery of orders, rub. |

||

| Amount of transported cargo, boxes |

||

| Transport mileage, km |

||

| Number of routes, units |

||

| Transport capacity utilization factor |

||

| Delivery costs per 1 km, rub. |

||

| The cost of transporting a unit of cargo (1st box), rub. |

Q is the carrying capacity of the car (120 boxes).

Table 3.6 shows the final data of the "Business Game". That is, for the transportation of 1440 boxes, the total costs amounted to 12,725 rubles, and the transportation of one box accounts for 8.84 rubles.

Conclusion

Application mathematical methods and models in logistics is necessary in cases where the problem is complex and it is impossible to solve it with the simplest methods based on work experience. In this case, an ill-conceived and scientifically unfounded decision can lead to serious consequences. There are quite a few examples of this in our life, in particular in logistics and economics. The use of mathematical methods and models allows the logistician to select the optimal or close to them solutions according to certain criteria. Naturally, these decisions are scientifically based, and the logistician making the decisions can be guided by them when choosing the final solution.

Since the cost of transportation depends on the amount of work performed and the funds spent on it, the main condition for its reduction is the growth of labor productivity of drivers and other employees. motor transport enterprises, saving material resources (reducing the cost of fuel, materials, spare parts, etc.), as well as reducing administrative - management expenses by rationalizing the management of motor transport enterprises.

Plays a huge role in reducing the cost of transportation effective organization transportation and complex mechanization of loading and unloading operations. Rational Decision these issues allows you to maximize the load capacity of vehicles and ensure their minimum downtime during loading and unloading.

Conducted studies on the example of the "Business Game" show that on transport enterprise change in the distance of transportation, has a significant impact on the cost. In our case, the cost is 8.84 rubles. To reduce the cost, this enterprise can use trailers, which dramatically increase the productivity of the car and contribute to an increase in the utilization rate of the cargo capacity of vehicles, and it is also necessary to increase the number of own vehicles.

Bibliography

Nerush Yu.M. Logistics: textbook. – 4th ed., revised. and additional – M.: Prospekt Publishing House, 2007. – 520 p.

Ilyenkova S.D. Production management. Textbook. – M.: UNITI, 2000.

Mirotin L.B. Logistics. – M.: Jurist, 2002.

Kurganov V.M. Logistic traffic flows. - M .: Publishing and Trade Corporation "Dashkov and K", 2003.

MOSCOW AUTOMOBILE AND ROAD STATE TECHNICAL UNIVERSITY (MADI)

Course work

by discipline: International road transport

On the topic: Development of an international route for the transportation of goods

Performed:

Sabirova I.A.

Moscow, 2014

Introduction

In this work, an international route will be developed. It is necessary to transport the cargo (lumber) in the export direction (from Sergiev Posad to Serbia, Nish), as well as in the import direction to take the cargo (mineral wool) from Sofia to Moscow by car. The chosen vehicles were a Volvo Fp2 tractor and a Renders RSCC 12-27 All connections semi-trailer.

To develop a route, you will need to choose a method of packaging the transported cargo, for which you will need to determine the mass and dimensions of the cargo unit, determine the location of the cargo in the body vehicle, choose the methods of loading and unloading. It is also necessary to present a graphic scheme of the route, indicate border crossing points, determine rest points for drivers, etc. Based on the results of the work, it is necessary to calculate and provide in the form of a table the main technical and operational indicators.

1. Packing and placement of cargo in the body of the vehicle. Fastening Requirements

Transportation of lumber is conditionally divided into three stages: transportation of freshly sawn timber to the sawmill (the place of its primary processing), delivery from the sawmill to the trading warehouse, transportation of sawn timber from the warehouse to the buyer. Almost each of the listed directions can be serviced by motor transport.

Transportation of freshly sawn wood and freed from branches and knots is carried out on semi-trailers-dissolutions, pipe-carriers, trolleys-dissolutions, which are often equipped with a special loading and unloading device. The movement of raw forest is regulated by enhanced security requirements. According to the rules for the transportation of raw lumber, a safety mount is necessary, since an unreliably fixed forest can break not only the body, but also the cab of the car.

At sawmills and wood processing plants, wood is turned into veneer, timber, boards, firewood, moldings. Coniferous lumber (spruce, pine, larch) is harvested with a length of at least 6 meters, or rather, taking into account an allowance of up to 6.30 m. In this case, the length of the car body cannot be less than 6.3 meters. Hardwood lumber (birch, alder, aspen) after processing has a length of at least 4 meters. Very rare oak - from 2.5 meters. Vehicles for the transportation of lumber from hardwood trees require a less specific one. This type of cut, such as moldings (floorboard, lining, glued laminated timber) can be of different lengths. Small lining, for example, can even be assembled into bundles.

For the transportation of wood, airborne vehicles with increased in height (extended) sides and reinforced racks are required. Also, crossbars (conics) are used to reinforce the sides.

The weight of wood depends on its moisture content, species, the number of voids during laying. The weight of raw pine wood is considered to be 800 kg/t, dried 600 kg/t, dry 500 kg/t. That is, freshly sawn or stored in damp conditions pine with a volume of 25 m 3 will weigh 20 tons. The body of a 20-ton truck with a volume of 92 m 3 will be filled with such a load by less than 1/3. For example, birch is denser and therefore heavier than pine. Thus, all calculations are relevant at the time of loading, taking into account the characteristics of wood.

The safety of timber and lumber during transportation is ensured by proper stacking and fixation with safety straps. It is possible to simplify the subsequent unloading of a large amount of wood by means of a crane when laying the bars (boards) in several tiers, shifting the transverse bars. In this case, it will be easy to pass the crane slings into the gaps formed.

If the transportation of wood is planned for a long distance or for export, then in order to preserve the lumber, they are processed special composition against pests and fungus, packed in a special film. For especially valuable forest species (oak, Siberian larch and pine), these measures are always important

Fig 1. An example of placing lumber on a pallet

Fig 2. Scheme and dimensions of the pallet.

Fig 3. Lumber layout side view

Based on the restrictions on the weight of the transported cargo in the EU countries for 5 main road trains of 40 tons and the curb weight of the road train and semi-trailer = 7350 + 7400 = 14200 kg, we can load our semi-trailer with a maximum of = 39000-14200 = 24800 kg.

g \u003d Qact / Qmax \u003d 14760 / 16200 \u003d 0.9

Gross train weight = curb weight of the tractor + curb weight of the semi-trailer + load capacity of the semi-trailer = 7350 + 7400 + 39000 = 53200 kg

The actual mass of the road train = the curb weight of the tractor + the curb weight of the semi-trailer + the actual mass of the semi-trailer loading = 6800+7400+25200=39400 kg.

Dimensions and weight of a unit of cargo.

The thickness of the mineral wool is 5 ... 10 cm. The width of mineral wool mats, as a rule, is 60 cm, and the length is 125 cm.

Mineral wool of different density is produced: from 11 to 350 kg/m 3 .

Packing and labeling of cotton wool must be carried out in accordance with the requirements of GOST 25880.

Cotton wool is supplied, as a rule, in the form of transport packages.

The dimensions of overpacks suitable for transportation by all modes of transport must comply with the requirements of GOST 24597. The use of overpacks of other sizes is allowed upon agreement with the transport ministries (departments).

For the formation of transport packages, it is recommended to use multi-turn packaging means: flat pallets in accordance with GOST 9078 and GOST 22831 with strapping, rack-mount pallets of the PS-0.5G type, box pallets in accordance with GOST 9570, as well as disposable packaging means: flat pallets in accordance with GOST 26381 with strapping, backing sheets with strapping.

The following materials can be used as strapping (means for fastening transport packages): steel wire according to GOST 3282, steel tape according to GOST 3560, GOST 6009 and GOST 503, aluminum wire rod grades AKLP-5T, AKLP-5PT according to GOST 13843, polyethylene tape with adhesive layer in accordance with GOST 20477, polyethylene shrink film in accordance with GOST 25951, metal and polymer tapes, steel and aluminum wire, synthetic film produced according to other regulatory documents and ensuring the safety of packages during the entire period of transportation and storage of cargo.

Rice. 4. Location of mineral wool on the pallet.

Rice. 5. Layout of transport pallets top view

Quantity in a pallet - 40.0 roll, weight of one pallet is 17 kg.

Based on the restrictions on the weight of the transported cargo in the EU countries for 4 main road trains of 38 tons and the curb weight of the road train and semi-trailer = 7350 + 8500 = 15850 kg, we can load our semi-trailer with a maximum of = 39000-15850 = 23150 kg.

Overall and weight dimensions do not exceed the internal dimensions and carrying capacity of semi-trailers.

Calculation of the coefficient of utilization of the load capacity of the semi-trailer.

g \u003d Qact / Qmax \u003d 22248 / 38000 \u003d 0.59

Comparison of the actual and design total mass of the road train.

Gross train weight = curb weight of the tractor + curb weight of the semi-trailer + load capacity of the semi-trailer = 6800 + 8500 + 22500 = 37800 kg

Actual weight of the road train = curb weight of the tractor + curb weight of the semi-trailer + actual weight of the semi-trailer loading = 6800+8500+37800=37548 kg

2. Technical and operational characteristics of automatic telephone exchange

Table 1. Technical and operational parameters of the tractor.

|

Name of parameters |

Conventions |

Units |

Parameter value |

||

|

Wheel formula |

|||||

|

Engine class |

|||||

|

Engine power |

|||||

|

On the front axle To the rear axle |

|||||

|

On the front axle To the rear axle |

|||||

|

Max speed |

|||||

|

turning radius |

|||||

|

Fuel tanks volume |

|||||

|

Tire size types |

|||||

|

Basic fuel consumption rate |

|||||

|

Year of issue |

|||||

|

Cost as of 01.10.2014: This model and this year of manufacture Similar model 2013-2014 |

|||||

|

Main dimensions: Overall length Overall width Overall height center distance From SSU to front point From SSU to front axle From SSU to rear axle From SSU to cab Rear axle to rear point |

Rice. 6 Volvo Fp2

Table 2. Technical and operational parameters of the semi-trailer

|

Name of parameters |

Conventions |

Units |

Parameter value |

||

|

Trailer type |

Container |

||||

|

Curb weight including: On the trailer trolley |

|||||

|

Permissible gross weight including: On the trailer trolley |

|||||

|

load capacity |

|||||

|

Dimensions: |

|||||

|

Inner dimensions: |

|||||

|

loading height |

|||||

|

Cargo space |

|||||

|

The cost of this model and this year of manufacture |

|||||

|

The cost of the 2014 model |

|||||

|

Main dimensions: From load pin to center of gravity Centerline to center of gravity Between the axles of the bogie Load pin to forward point Centerline to rear Between the center axle and load pin |

Rice. 7. Semitrailer Renders RSCC 12-27 All connections.

3. Devices for monitoring the mode of work and rest of the driver

Tachograph - onboard technical means measurement, designed for continuous indication and registration in automatic mode of the speed, vehicle mileage, periods of work and rest of drivers.

The use of a tachograph allows:

Improve traffic safety;

Participate in transportation on the territory of the CIS countries and the European Union; - ensure the legal protection of drivers;

Objectively pay off with the customer of transportation;

Avoid "left" flights;

Objectively assess the quality of route planning and the professional skills of the driver.

In accordance with international requirements for the AETR countries on the organization of the work and rest regime for vehicle drivers, trucks, making international transportation, as well as buses of international and intercity communication, must be equipped with devices for monitoring the mode of work and rest of drivers - tachographs. The experience of countries where the use of tachographs is mandatory convincingly proves a 30% reduction in accidents, a 3-fold reduction in unforeseen repairs. The presence of a tachograph eliminates the need for the driver to prove his case to the traffic police.

Tachograph characteristics:

The digital tachograph DTCO 1381 records all the necessary data, such as vehicle driving and stopping times, speed readings, engine revolutions. All this is recorded in the device's memory, from where they can be easily read electronically.

Model DTCO 1381 is a digital tachograph with a user-friendly LCD display (2x16 characters). There are two slots for smart cards.

The tachograph DTCO 1381 uses personal cards with a memory of up to 28 days (ordered separately).

The memory of the device is designed to store information up to 1 year.

The memory stores all data related to the vehicle, including driver data.

Rice. 8. Tachograph DTCO 1381

Tachograph indicators:

Removal of the front cover 109 mm

Front cover tilt angle 69 degrees - ISO 7736 radio format

Convenient LCD display 2x16 characters - Automatic recording of driving periods

Output for optical transmission data. Signal for monitoring the presence of a chart disk, closing the lid, tachograph serviceability

Pre-selected speed limit alarm

Automatic shutdown of the chart drive motor after 25 hours (reduction of current consumption)

Possibility of automated processing of chart discs

Tachograph front panel indication:

Speed

date and time

Total and daily mileage

Drivers working hours

Control of the tachograph

Tachograph recording indicators:

Speed

Periods of work and rest

Opening the cover of the tachograph. Recording time per disc 24 hours

1 or 2 drivers

Time periods:

driving time

Time of attendance at the workplace

Other work time

Breaks and rest time

Upper limit of speed measurement range: 125 km/h (140.180 km/h - on request).

The upper limit of the speed measurement range: 3300 rpm (optional).

Working temperature: from -25 °С to +70 °С

Rated supply voltage: 24V (12V - on request)

Pulse frequency range: 4000 - 25000 imp/km

Tachograph installation angle: from 0° to 90°

Input: Speed sensor, diagnostic socket

Outputs: Speed pulses, diagnostic socket, optical interface

Permissible error: 3 km/h; 200 rpm; 5 sec/day; 1%/km

Degree of protection: RL 95/94/EG ISO7637

Body Material: Galvanized Steel

Weight: 1350 g.

Additional equipment: Additional recorder; signal output 4 pulses/m path; vehicle speed and engine speed signal outputs for controlling external devices.

cargo transport driver export

4. Determining the route of cargo delivery

Figure 10. Route 1: Sergiev Posad, Russia - Nish, Serbia.

Figure 11. Route 2: Belgrade, Serbia - Tuchkovo, Russia.

Table 3. Length of sections of cargo delivery routes

|

Vehicle mileage across countries, km |

Water delivery, km |

Railway delivery, km |

Total route length, km |

||||||||

|

Belarus |

Slovakia |

||||||||||

|

Export direction: laden |

|||||||||||

|

Empty |

|||||||||||

|

Import direction: laden |

|||||||||||

|

Empty |

|||||||||||

|

total, including: |

|||||||||||

|

laden |

|||||||||||

|

Empty |

According to the European Agreement on Work and Rest for Drivers (AETR), the daily duration of driving a motor vehicle must not exceed nine hours, and after continuously driving a motor vehicle for four and a half hours, the driver must take a break of at least 45 minutes, unless there is a period recreation. This break may be replaced by breaks of at least 15 minutes each distributed over the driving period so that they add up to at least 45 minutes.

Within every 24 hours, the driver must have at least 11 hours of uninterrupted daily rest. The daily rest period can be used on a motor vehicle if it has a sleeping place and it is motor vehicle is in the parking lot.

Table 4. Driver's schedule of work and rest.

|

current time |

Duration, hour |

Mileage, km |

name technologist |

||||||

|

Hours, min |

PBX management |

Other times |

For tech. operational |

||||||

|

ELV + medical examination |

|||||||||

|

Simple for loading, tp1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Rest and food |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Border point |

|||||||||

|

Weekly rest |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Border point |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP1 |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Simple for unloading |

|||||||||

|

Rest and food |

|||||||||

|

Easy for loading |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Rest and food |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Weekly rest |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Border point |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Movement with cargo to GP2 |

|||||||||

|

Movement with cargo to GP2 |

5. Technical and operational indicators of the route

1. Statistical coefficient of utilization of the carrying capacity of the vehicle

in export direction

Est \u003d qe / q \u003d 36.2 / 36.2 \u003d 1

in the import direction

East = qi / q = 36.2/ 36.2 = 1

2. Utilization rate of mileage per revolution

in vol \u003d L gr total / L total \u003d 4674 / 5082 \u003d 0.92

3. Volume of cargo transportation per vehicle turnover

Q about \u003d q e + q and \u003d 36.2 + 36.2 \u003d 72.4 tons

4. Transport work per vehicle turnover

W about \u003d q e * l e gr + q and * l and gr \u003d 36.2 * 2427 + 36.2 * 2247 \u003d 87857.4 + 81341.4 \u003d 169198.8 tkm

5. Duration of the return trip of the road train

T about \u003d ((L e + L and) / (T d * V t cf)) + n p * t p + n p * t p + t e pp * t and pp

T about = ((2504+2578)/(9*50)) + 2*1 + 2*1 +12/24+11/24= 16.24 days.

Adjusted value of round trip duration

T about to = T about + 2*|T about /5|= 16.24 + 2 *|16.24/5| = 20.24 days

6. Estimated annual number of road train round trips

N year \u003d D to * b c / T about to \u003d 365 * 0.8 / 22.24 \u003d 13 about.

7. Standardized fuel consumption for a turnaround trip of a road train

Qn \u003d 0.01 * (Hsa * S + Hw * W) * (1 + 0.01 * D) Hsa \u003d Hs + Hw * Gpr

Нsa=15+1*6.54=21.54

Qн=0.01*(21.54*5082+1*169198.8)*1.1=3065

Hs - base fuel consumption rate for Volvo Fp3 (15 l/100 km)

Hw - fuel consumption rate for the transportation of payload (1 l / 100 km)

D - work allowance (10%)

Gpr - weight of the equipped semi-trailer (6540 kg) S - mileage (5082 km) W - transport work(169198.8 tkm)

Hsa - fuel consumption rate per mileage of a road train as part of a Volvo Fp3 tractor and a semi-trailer Renders RSCC 12-27 All Connections

8. Average fuel consumption per 1 km per revolution

Q cf 1km = Q n / L total = 3605/5082=0.6

9. Duration of cargo delivery from the consignor to the consignee:

settlement

T e dost \u003d (L e gr / (T d * V t cf)) + n e p * t p + n e r * t p + t e pp \u003d (2427 / (9 * 50)) + 1 * 1 +1*1+12/24=7.89 days

T and dost \u003d (L and gr / (T d * V t cf)) + n and p *t p + n and p *t p + t and pp \u003d (2247 / (9 * 50)) + 1 * 1 +1*1+11/24=7.44 days

corrected

T e access to = T e access + | T e dost / 5 | * 2 \u003d 7.89 + 1 * 2 \u003d 9.89 days.

T and access to = T and access + | T and reach /5|*2 = 7.44+1*2=9.44 days.

6. List of documents required for the delivery of export and import cargo

Documents for the carrier

· driver's license

driver's checkbook

Documents on the vehicle

certificate of vehicle registration

permission to enter the country and to move in transit

certificate of civil liability insurance

certificate of approval of the vehicle for transportation under special conditions

Documents for transported goods

· International consignment note

TIR Carnet

· Freight customs declaration

· Waybill

List of used literature

1. A course of lectures on the discipline "International road transport", Atrokhov N.A.

2. Information system for cargo transportation.

3. Information about the semitrailer.Chassis/15207864/1

4. Rules for the transportation of mineral wool.

Similar Documents

Determining the route of cargo delivery. Packing and placement of cargo in the body of the vehicle. Calculation of technical and operational indicators of the route. Devices for monitoring the mode of work and rest of the driver. Calculation of actual loads on the axles of the road train.

term paper, added 01/15/2013

Packing and placement of cargo in the body of the vehicle. Technical and operational characteristics of automatic telephone exchange. Calculation of axial loads. Devices for monitoring the mode of work and rest of the driver. Description of the tachograph KIENZLE 1324. Determination of the route of cargo delivery.

term paper, added 03/02/2011

Development of a mixed route using road and sea transport for the transportation of cargo (22 rolls of sheet steel of 2.5 tons) from Milan to Murmansk, using containers. Determination of the optimal scheme for the delivery of this cargo.

term paper, added 11/28/2013

The image of the scheme of the automobile route for the delivery of goods. Development of a route for the delivery of goods in the form of a route scheme on a map, a list of destinations, a table of lengths of sections across the territory of countries, broken down into loaded and empty runs.

practical work, added 11/20/2014

Justification for the choice of supplier, delivery route. Characteristics of the design situation. Formation of a block of initial data. Choice of supplier and route. Determination of the optimal route for the transportation of goods along the ground section, type of vehicle.

term paper, added 02/12/2009

The volume of bulk and general cargo. Determining the optimal transportation route involving three modes of transport and determining the transportation distance along the selected routes. Calculation of delivery time, cost by rail and road.

test, added 05/19/2014

Scheme of the international route. Scheduling drivers. Order-order for chartering a vehicle. Ensuring control over private drivers and technical serviceability of vehicles. Medical examination of the driver.

thesis, added 01/24/2012

Determination of the route and methods of transportation of perishable goods. Technology of maintenance of refrigerated rolling stock on the direction. Development of an approximate scheme for the layout of a refrigerated warehouse. Determination of the maximum distance between points.

term paper, added 10/04/2012

Economic comparison of logistics schemes for cargo transportation various types transport on the route Gomel - Nizhny Novgorod. Determination of the route and cost components. The main list of documents for passing the border and customs control.

thesis, added 08/26/2012

Establishment of a possible route for the delivery of goods. Calculation of tariffs for reloading operations and transportation of goods by rail and water transport. Determination of a rational scheme for its delivery using the distributive linear programming method.

The choice of the route for carrying out the transportation of goods is most often carried out after calculating the total cost of delivery in different ways. This methodology includes calculations of all investments for each route option (taking into account not only the distance and fuel consumption, but also the characteristics of each mode of transport and service needs). At the same time, it is not always necessary to choose the cheapest route - in some cases, an increase in costs for one item of expenditure leads to a decrease in spending as a whole. This condition must be taken into account by specialists performing calculations.

The development of the route is carried out by the forwarding department of the carrier company responsible for the execution of transportation for a specific order. Calculations are necessary when organizing the transportation of a new type of cargo or compiling new routes for already known cargo. Ideally, approximately 3-4 options for moving cargo from the initial to the final point are compiled, after which they are evaluated in detail for profitability and compared with each other.

For clarity, let's imagine that we need to transport 20 thousand tons of rubber shoes from Kohtla-Jarve to the port of Dalian (China). Let us assume that the customer of the transportation, who is also the buyer of the specified products, pays most of the costs. The transportation organizer must organize the main transportation with shipment at the transshipment point (port) and further delivery to the exact place of receipt of the goods by the buyer. The following transportation options have been developed:

- From Kohtla-Jarve we deliver goods by railway to the port of Sillamäe, then along the sea routes to the port of Dalyan. Approximate total cost of such transportation: $567,200

- From Kohtla-Järve by rail to the port of Muuga, then by sea to the port of Dalyan. Preliminary calculation of the total cost of transportation: 820400 c.u.

- It is also possible to deliver the goods by rail from Kohtla-Järve to the port of Dalian directly. The cost of this delivery option is estimated at $1,130,000.

Route options are ready. It would seem obvious that in the economic sense the first option is the most profitable. But the organizer of transportation will not necessarily choose it, as a number of other factors should be evaluated. The most important among them are the duration of transportation, the risk of loss or damage to cargo, the likelihood of unexpected costs and delays in transit. The approval of the route is usually made by the customer of the transportation, i.e. the owner of the cargo. As soon as the route is determined, the organizer of the transportation looks for transport companies to carry it out and concludes contracts with them for the provision of services.

Calculation of logistics costs for transport. Tariff approval.

The logistics costs of transport depend to a greater extent on the real cost of transporting goods by various modes of transport. To determine this amount, the concepts of tariff and freight are used. In the first case, we are talking about ground transportation, the cost of which is determined by the owner of the vehicle and is valid for a certain time period. Freight is the cost of a specific transportation by sea, negotiated by the owner of the vehicle and the customer.

The cost of transporting goods by road is determined transport company at your discretion. At the same time, tariffs for customers are developed in accordance with the settlement system adopted by the organization. In practice, time-based tariffs are most often used, piecework or based on the calculation of conventional units of work. At the same time, the owner of the transport has the right to develop different payment schemes for different customers (for example, discounts for regular customers or for large shipments), transport units, etc.

Separate tariffs are developed for each type of transport. Payment transport services should be carried out in such a way that the owner makes a profit, as well as fully covers the costs of maintaining the transport. At the same time, for the buyer, the cost of transportation should not be too high and different price ranges should be maintained.

For rail transport total cost delivery form the following conditions:

- the speed of the cargo in transit

- features of cargo placement: shipment by containers, wagons, small lots or tons

- route length

- the need to use special equipment: standard wagons or platforms that provide a special temperature regime, tanks.

- volume of transported products

- special conditions for the owner of wagons or tanks

Tariffs are determined by tariff rates that determine the cost of transportation. From the side of an ordinary buyer of goods at retail or small wholesale, tariffs can be classified as transportation costs. For the owner of vehicles, tariffs are the main tool that generates income.

Standard formula for calculation tariff rate as follows:

T - tariff rate

c - cost of transportation

r - profit (%)

For different modes of transport, the following types of tariffs apply:

Vehicles:

- piece-work payment

- terms of paid transport - tons / hours

- by truck transport arena time

- by distance traveled (km)

- rolling stock haulage tariffs

- contractual terms of payment

Railway transport:

- uniform tariffs

- exceptional

- preferential

- regional

Sea transport:

- for permanent lines

- freight rates for single shipments

For river transport, the tariffs are set by the shipping company.

For a linear tariff, rates may vary depending on the characteristics of the transported products, the total size of the lot, the point of loading and unloading.

For different types cargo, the following schemes for calculating the cost of its transportation are used:

- Cool tariffs involve the creation tariff scale for various classes of cargo and determining the cost of delivery by category and subcategory of specific products.

- Line-item tariffs involve taking into account all types of cargo carried by name and developing a tariff rate for each of them.

- Mixed tariffs are a system in which rates are applied for some goods by class, and for others - by article.

The size of the tariff rate is determined by a number of conditions:

- type of cargo and the ratio of mass and volume indicators

- the duration of loading and unloading, the need to use special equipment to perform these works

- cargo value ( material liability carrier), as well as its danger to the vehicle.

When calculating the ratio of volume and mass for heavy loads, tariffs are developed by weight, and for light ones - by volume (m 3). Similarly, for cargo that is more labor-intensive in loading, the tariffs will be higher than for conveniently packaged cargo that does not require special conditions for rigging.

High tariff rates are also used for products with high material value. Most often, the cost of delivery increases by a certain percentage of the cost of products specified in the insurance policy.

Some other factors also affect the size of the tariff rate:

- Acceptance by the sender of the cargo of the maximum rate that ensures the shipment of the cargo without risk.

- Influence government agencies or freight forwarding companies, aimed at increasing the cargo flow and attracting new customers to the industry.

When delivering cargo by sea, it is worth considering the types of ports. They are mandatory and optional regarding the route of the transport unit. Accordingly, for unloading at an optional port, the owner of the transport will increase the interest rate to reimburse his own expenses.

When concluding a contract for the carriage of goods between the customer and the owner of the transport, an agreement is reached on payment for the services provided. When discussing tariffs, the conditions under which they operate should be taken into account:

- Depending on the type of cargo, a method for determining its weight or volume is selected.

- All additional payments are negotiated, for example, for the delivery of dangerous or valuable cargo.

- If the calculation is made at a standard rate, the services must be listed in the contract. Also, the owner of the vehicle must notify the procedure for the provision of all other services for a separate fee.

The standard tariff is also called "linear", it includes the following services:

- Shipment and short-term storage of cargo at the warehouse of the transportation organizer

- Loading products onto the selected vehicle

- Sorting in the transport compartments of the components of the cargo, packaging and securing it before shipment

- Moving cargo along the route

- Unloading at the final destination

- Storage at the warehouse of the transportation organizer (if necessary)

- Transfer of cargo to the transportation customer

"This article was prepared specifically for the site. Copying an article is allowed only with an active link to our site."

Page 1

used to develop transportation routes. following algorithm: The fully loaded vehicle travels to the farthest consignee, unloads the ordered quantity of cargo, and then travels to the nearest second location, etc., until it is completely unloaded and returns back to the supplier.

After the formation of the route by complete enumeration, the shortest way to bypass the consignees included in this route is found.

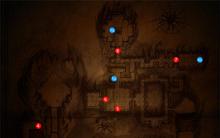

Of all the consignees, we select the point that is located farthest from the GOP - GPP No. 3. Then we select a consumer located near point No. 4, so that it is rational to make a route - GPP No. 4. The distance between these points is 26 km. In GPP No. 3 we unload 3 full containers (we load 3 empty ones). Then the car is sent to GPP No. 4. There we unload 6 full containers (we load 6 empty ones). Then we follow to GPP No. 6. In it we unload 3 full containers (we load 3 empty ones). The sum of the needs of these points coincides with the number of containers transported by the vehicle. Then the car returns to the GOP (terminal). Route No. 1 is formed. All other routes are formed similarly (Fig. 4)

Route number 1

Route number 2

Route number 3

Route number 4

Fig.4. Formed routes

The technological process of the rolling stock operation along the delivery and assembly route No. 1 is as follows: the car leaves the ATP at 7:52 without cargo and, having passed zero mileage ln, arrives at the consignor (supplier). There, 12 containers with a total weight of 7.5 tons are loaded onto the arrived car using a forklift. A fully loaded car goes to the farthest point No. 3 and unloads 3 containers there and immediately loads 3 empty containers. Then the car goes to consignee No. 4, unloads 6 containers there and picks up 6 empty containers. Then the car goes to the consignee No. 6, unloads 3 containers there and picks up 3 empty containers. Then, with 6 empty containers, it returns to the shipper. This technological process transportation of goods can be repeatedly repeated on this, as well as on others, routes.

Route number 1

Rice. 6. Scheme of route No. 1

Table 4. Route Analysis #1

|

Route segments |

Number of containers in the car | |||

|

laden |

empty |

|||

Quality requirements

Peat resources Milling peat extraction

Closed Joint Stock Company Transtelecom

Setting up Wi-Fi equipment

Pasteurization drawer for the selection of "heads" during rectification